Grades

categories

Categories

enquire now

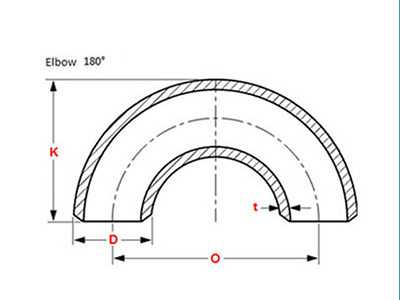

180 Degree Elbow

Alloyed Sustainables LLP stands as a prominent Manufacturer and Exporter of 180-degree Butt Weld Fittings. Our precision-crafted fittings cater to diverse industries globally, ensuring reliability and quality in every piece. We prioritize both excellence and affordability, offering competitive prices without compromising quality. This remains committed to providing exceptional 180-degree butt weld fittings that meet varied application needs reliably.

Description:

A 180-degree elbow, also known as a U-turn or U-bend elbow, is a type of pipe fitting used to change the direction of fluid flow by 180 degrees in a piping system. It’s designed to connect two pipes or tubes of the same nominal diameter and allows for a complete reversal of flow direction. We manufacture 180-degree elbows in accordance with the specifications outlined by ASTM, ASME, and DIN standards. This commitment to meeting internationally recognized standards ensures the quality, performance, and reliability of our elbow fittings.

Key Features of 180 Degree Elbow:

- Leak-Resistant: Welded directly to pipes, forming a strong, seamless connection that minimizes the risk of leaks.

- Smooth Flow: Internal smoothness reduces turbulence and pressure drop, optimizing fluid flow efficiency.

- Durability: Engineered to endure high pressures and temperatures, suitable for industrial applications.

- Space Efficient: Ideal for reversing pipe direction when space is limited or specific layouts are required.

- Corrosion Resistance: Depending on material choice, it can withstand corrosive environments effectively.

Application across Industries:

- Oil and Gas: Our 180-degree butt weld fittings play a crucial role in oil and gas pipelines, ensuring seamless fluid flow and reliable connections for the transportation of petroleum products.

- Chemical Processing: These fittings are essential in chemical plants, providing leak-resistant connections that maintain the integrity of fluid handling systems, even in corrosive environments.

- Power Generation: In power plants, our fittings contribute to efficient steam and water circulation, supporting the generation of electricity through secure and piping connections.

- Water Treatment: Our fittings find applications in water treatment facilities, facilitating the proper direction of fluids and chemicals for purification and distribution.

We provide 180-Degree Elbows manufactured using a variety of materials and grades, addressing the distinct needs of our customers and a broad spectrum of industries.

STAINLESS STEEL & DUPLEX STEEL 180 Degree Elbows:

Specifications:

- Size: 1/2″ to 36NB”, ANSI/ASME B 16.9, MSS-SP-43

- Schedule: 10S/40S/80S/160S/XXS

- Stainless Steel : ASTM A 403 WP – TP 304/ 304H/ 304L/ 316/ 316H/ 316L/ 316Ti/ 309/ 310/ 317L/ 321/ 347/ 904L, Alloy 20

- Duplex Steel: ASTM A815- UNS S31803, S32750, S32760, S32205

ALLOY STEEL, CARBON STEEL & LTCS 180 Degree Elbow:

Specifications:

- Size: 1/2″ to 36NB”, ANSI/ASME B 16.9

- Schedule: 10S/40S/80S/160S/XXS

- Alloy Steel: ASTM A 234 WPB, WP5, WP9, WP11, WP12, WP91

- Carbon Steel: ASTM A 234 WPB, IS 1239 PART II

- Low Temperature Carbon Steel: ASTM A-420 WPL6

- Other Services: Hot Dip Galvanizing, Sand Blasting

COPPER & NICKEL ALLOYS 180 Degree Elbow:

Specifications:

- Size: 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule: 10S/40S/80S

- Copper Nickel: C70600(90:10), C71500(70:30), C71640

- Nickel: UNS N02200, N02201

- Monel: UNS N04400

- Inconel: UNS N06600, N06601, N006625, N08800, N08810, N08825

- Hastelloy: UNS N10276, N06022, N10665, N06455

- SMO 254: Grade UNS S31254

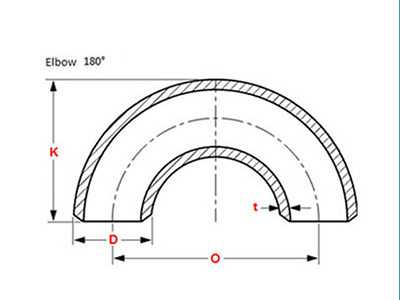

180° ELBOW BUTTWELD FITTINGS

Alloyed Sustainables LLP stands as a prominent Manufacturer and Exporter of 180-degree Butt Weld Fittings. Our precision-crafted fittings cater to diverse industries globally, ensuring reliability and quality in every piece. We prioritize both excellence and affordability, offering competitive prices without compromising quality. Alloyed Sustainables LLP remains committed to providing exceptional 180-degree butt weld fittings that meet varied application needs reliably.

Description:

A 180-degree elbow, also known as a U-turn or U-bend elbow, is a type of pipe fitting used to change the direction of fluid flow by 180 degrees in a piping system. It’s designed to connect two pipes or tubes of the same nominal diameter and allows for a complete reversal of flow direction. We manufacture 180-degree elbows in accordance with the specifications outlined by ASTM, ASME, and DIN standards. This commitment to meeting internationally recognized standards ensures the quality, performance, and reliability of our elbow fittings.

Key Features of 180 Degree Elbow:

- Leak-Resistant: Welded directly to pipes, forming a strong, seamless connection that minimizes the risk of leaks.

- Smooth Flow: Internal smoothness reduces turbulence and pressure drop, optimizing fluid flow efficiency.

- Durability: Engineered to endure high pressures and temperatures, suitable for industrial applications.

- Space Efficient: Ideal for reversing pipe direction when space is limited or specific layouts are required.

- Corrosion Resistance: Depending on material choice, it can withstand corrosive environments effectively.

Application across Industries:

- Oil and Gas: Our 180-degree butt weld fittings play a crucial role in oil and gas pipelines, ensuring seamless fluid flow and reliable connections for the transportation of petroleum products.

- Chemical Processing: These fittings are essential in chemical plants, providing leak-resistant connections that maintain the integrity of fluid handling systems, even in corrosive environments.

- Power Generation: In power plants, our fittings contribute to efficient steam and water circulation, supporting the generation of electricity through secure and piping connections.

- Water Treatment: Our fittings find applications in water treatment facilities, facilitating the proper direction of fluids and chemicals for purification and distribution.

We provide 180-Degree Elbows manufactured using a variety of materials and grades, addressing the distinct needs of our customers and a broad spectrum of industries.

STAINLESS STEEL & DUPLEX STEEL 180 Degree Elbows:

Specifications:

- Size: 1/2″ to 36NB”, ANSI/ASME B 16.9, MSS-SP-43

- Schedule: 10S/40S/80S/160S/XXS

- Stainless Steel : ASTM A 403 WP – TP 304/ 304H/ 304L/ 316/ 316H/ 316L/ 316Ti/ 309/ 310/ 317L/ 321/ 347/ 904L, Alloy 20

- Duplex Steel: ASTM A815- UNS S31803, S32750, S32760, S32205

ALLOY STEEL, CARBON STEEL & LTCS 180 Degree Elbow:

Specifications:

- Size: 1/2″ to 36NB”, ANSI/ASME B 16.9

- Schedule: 10S/40S/80S/160S/XXS

- Alloy Steel: ASTM A 234 WPB, WP5, WP9, WP11, WP12, WP91

- Carbon Steel: ASTM A 234 WPB, IS 1239 PART II

- Low Temperature Carbon Steel: ASTM A-420 WPL6

- Other Services: Hot Dip Galvanizing, Sand Blasting

COPPER & NICKEL ALLOYS 180 Degree Elbow:

Specifications:

- Size: 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule: 10S/40S/80S

- Copper Nickel: C70600(90:10), C71500(70:30), C71640

- Nickel: UNS N02200, N02201

- Monel: UNS N04400

- Inconel: UNS N06600, N06601, N006625, N08800, N08810, N08825

- Hastelloy: UNS N10276, N06022, N10665, N06455

- SMO 254: Grade UNS S31254