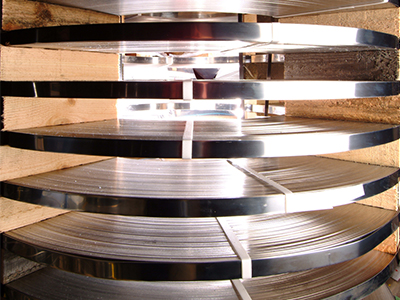

PRECISION SLIT COILS

Alloyed Sustainables LLP serves as a manufacturer, supplier, and exporter of precision slit coils located in India. Our commitment lies in ensuring the production of precision slitting coils through a reliable and fitting process. Rigorous quality assessments are conducted to ensure their durability, enabling extended mechanical longevity and optimal industrial performance. As providers of precision slitting coils, we offer a diverse range of forms, sizes, and specifications to align with client needs and preferences.

Description:

Precision slit coils refer to narrow strips of metal or other materials that have been cut to precise dimensions using a slitting process. This process involves cutting a large roll or coil of material into narrower strips of a consistent width. The resulting slit coils are commonly used in various industries, including manufacturing, automotive, construction, and electronics. Alloyed Sustainables LLP offers a diverse selection of precision slit coils available at various price points and specifications. Our precision slit coils are renowned for delivering optimal machining performance and exceptional corrosion resistance characteristics. These coils are engineered to provide the utmost durability and longevity, particularly in corrosive environments.

Key Features of Precision Slit Coils:

- Accurate Dimensional Precision: Precision slit coils are meticulously crafted to adhere to exacting dimensions, ensuring consistency and uniformity across each coil strip.

- Superior Machinability: These coils are engineered for exceptional machinability, allowing for smooth and precise manufacturing processes that yield high-quality end products.

- Enhanced Corrosion Resistance: Precision slit coils are designed to exhibit remarkable resistance to corrosion, making them well-suited for deployment in challenging environments where corrosion is a concern.

- Tailored Specifications: These coils are available in a wide array of forms, sizes, and specifications, providing versatility and catering to the diverse needs of various industries and applications.

- Optimal Material Integrity: Precision slit coils maintain the integrity of the base material, as the slitting process is carried out with precision to prevent any compromise to the material’s structural properties.

- Smooth Edges: The slitting process ensures that the edges of the coil strips are uniformly smooth, which is essential for seamless integration into production processes and end-use applications.

- Minimized Material Waste: Precision slitting minimizes material wastage, promoting sustainable practices by efficiently utilizing raw materials.

Application across Industries:

- Automotive: Precision slit coils contribute to the automotive sector by providing durable materials for parts like springs, brackets, and connectors, ensuring both performance and safety.

- Construction: In construction, precision slit coils are used to create corrosion-resistant structural components and roofing materials, maintaining building integrity over time.

- Electronics: With precise dimensions, precision slit coils are crucial in electronics manufacturing, ensuring reliability for components like connectors and contacts.

- Energy and Utilities: These coils find use in power generation equipment and renewable energy systems, thanks to their durability and suitability for power transmission.

- Aerospace: Precision slit coils play a vital role in aerospace, providing strength and reliability for aircraft components like brackets and panels.

- Oil and Gas: Precision slit coils resist corrosion and mechanical stress, making them valuable in oil and gas applications for pipelines and equipment.

Precision Slit Coils are available in a wide range of standard lengths, thicknesses, widths, and hardness levels to suit the diverse needs of our clients and various industrial applications.

STANDARD SPECIFICATION

-

- Thickness: 0.01mm – 6mm

- Standard: ASTM A240 / ASME SA240,B162, B127, B168, B443, B575 and many more precision coil

- Length: 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, as per customer’s requirement

- Width: 3.2mm – 1500mm & Above

- Hardness: Annealed – Pickled (soft), Soft, Hard, Half Hard, Quarter Hard, Spring Hard , 1/4 hard, Yi hard,3/4 hard , full hard , extra hard

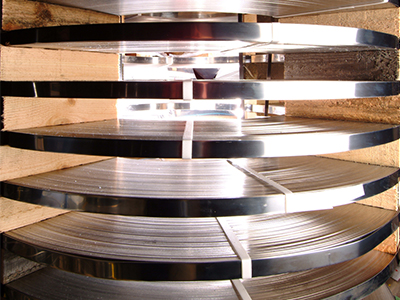

PRECISION SLIT COILS

Alloyed Sustainables LLP serves as a manufacturer, supplier, and exporter of precision slit coils located in India. Our commitment lies in ensuring the production of precision slitting coils through a reliable and fitting process. Rigorous quality assessments are conducted to ensure their durability, enabling extended mechanical longevity and optimal industrial performance. As providers of precision slitting coils, we offer a diverse range of forms, sizes, and specifications to align with client needs and preferences.

Description:

Precision slit coils refer to narrow strips of metal or other materials that have been cut to precise dimensions using a slitting process. This process involves cutting a large roll or coil of material into narrower strips of a consistent width. The resulting slit coils are commonly used in various industries, including manufacturing, automotive, construction, and electronics. Alloyed Sustainables LLP offers a diverse selection of precision slit coils available at various price points and specifications. Our precision slit coils are renowned for delivering optimal machining performance and exceptional corrosion resistance characteristics. These coils are engineered to provide the utmost durability and longevity, particularly in corrosive environments.

Key Features of Precision Slit Coils:

- Accurate Dimensional Precision: Precision slit coils are meticulously crafted to adhere to exacting dimensions, ensuring consistency and uniformity across each coil strip.

- Superior Machinability: These coils are engineered for exceptional machinability, allowing for smooth and precise manufacturing processes that yield high-quality end products.

- Enhanced Corrosion Resistance: Precision slit coils are designed to exhibit remarkable resistance to corrosion, making them well-suited for deployment in challenging environments where corrosion is a concern.

- Tailored Specifications: These coils are available in a wide array of forms, sizes, and specifications, providing versatility and catering to the diverse needs of various industries and applications.

- Optimal Material Integrity: Precision slit coils maintain the integrity of the base material, as the slitting process is carried out with precision to prevent any compromise to the material’s structural properties.

- Smooth Edges: The slitting process ensures that the edges of the coil strips are uniformly smooth, which is essential for seamless integration into production processes and end-use applications.

- Minimized Material Waste: Precision slitting minimizes material wastage, promoting sustainable practices by efficiently utilizing raw materials.

Application across Industries:

- Automotive: Precision slit coils contribute to the automotive sector by providing durable materials for parts like springs, brackets, and connectors, ensuring both performance and safety.

- Construction: In construction, precision slit coils are used to create corrosion-resistant structural components and roofing materials, maintaining building integrity over time.

- Electronics: With precise dimensions, precision slit coils are crucial in electronics manufacturing, ensuring reliability for components like connectors and contacts.

- Energy and Utilities: These coils find use in power generation equipment and renewable energy systems, thanks to their durability and suitability for power transmission.

- Aerospace: Precision slit coils play a vital role in aerospace, providing strength and reliability for aircraft components like brackets and panels.

- Oil and Gas: Precision slit coils resist corrosion and mechanical stress, making them valuable in oil and gas applications for pipelines and equipment.

Precision Slit Coils are available in a wide range of standard lengths, thicknesses, widths, and hardness levels to suit the diverse needs of our clients and various industrial applications.

STANDARD SPECIFICATION

-

- Thickness: 0.01mm – 6mm

- Standard: ASTM A240 / ASME SA240,B162, B127, B168, B443, B575 and many more precision coil

- Length: 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, as per customer’s requirement

- Width: 3.2mm – 1500mm & Above

- Hardness: Annealed – Pickled (soft), Soft, Hard, Half Hard, Quarter Hard, Spring Hard , 1/4 hard, Yi hard,3/4 hard , full hard , extra hard