In industries where incredibly corrosive environments are a day by day project, the selection of materials becomes vital for safety, performance, and longevity. One such material that has received giant reputation is Hastelloy C22, an alloy designed to thrive under the harshest chemical conditions. This alloy’s corrosion resistance and versatility have made it indispensable in various fields. In particular, Hastelloy C22 coils play a important role in applications where exposure to corrosive substances is inevitable

What is Inconel 600?

Inconel 600 also referred to as Inconel Alloy 600, is composed of approximately 72% nickel, 16% chromium, and trace amounts of iron. This alloy exhibits excellent resistance to heat, corrosion, and stress in harsh environments, making it suitable for demanding applications like chemical processing, aerospace, and marine engineering.

The alloy conforms to several standards, including the Inconel 600 ASTM Standard, which ensures its mechanical and chemical properties meet industrial requirements.

Common Forms of Inconel 600

1. Inconel 600 Sheets and Plates

- Description : Sheets and plates of Inconel 600 are thin, flat forms used extensively in applications requiring high strength and corrosion resistance.

- Applications : Ideal for heat exchangers, boiler components, and chemical storage tanks.

- Material Properties : Their formability and resistance to oxidation under extreme temperatures make them invaluable in the manufacturing industry.

2. Inconel 600 Pipes and Tubes

- Description : Available as seamless or welded variants, these are cylindrical forms used for fluid or gas transport under high pressure or heat.

- Applications : Widely used in nuclear reactors, gas turbines, and petrochemical plants.

- Material Properties : Excellent stress rupture strength and thermal stability ensure longevity in high-pressure systems.

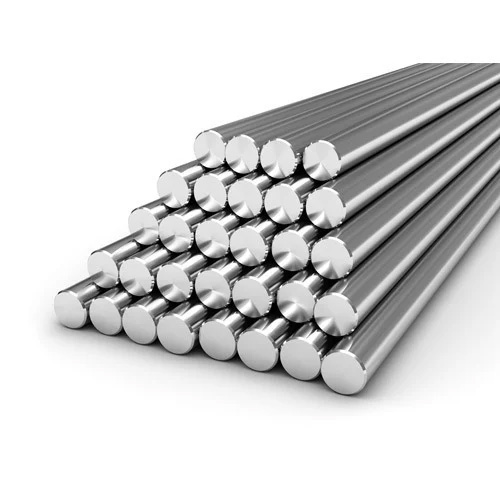

3. Inconel 600 Rods and Bars

- Description : These solid cylindrical forms come in varying diameters and lengths for machining or structural support.

- Applications : Commonly utilized in pump shafts, fasteners, and marine components.

- Material Properties : High tensile strength and resistance to saltwater corrosion make them ideal for offshore and naval applications.

4. Inconel 600 Wires

- Description : Thin, flexible wires made from Inconel 600 material are essential for applications requiring high ductility and electrical conductivity.

- Applications : Extensively used in electrical heating elements, springs, and safety lock wires.

- Material Properties : Resistance to creep and mechanical wear ensures reliability in high-temperature environments.

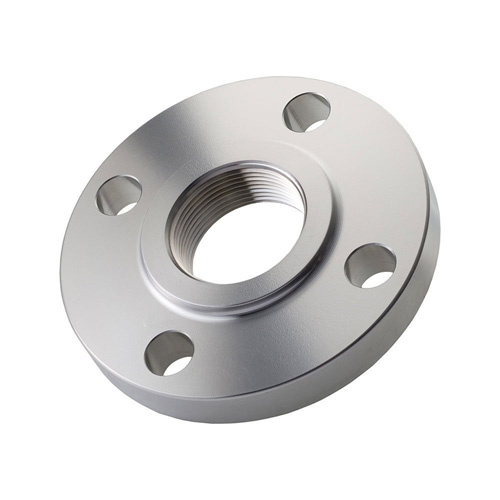

5. Inconel 600 Flanges

- Description : These are ring-shaped components used to connect pipes, valves, or equipment in industrial setups.

- Applications : Found in high-pressure pipelines, reactors, and exhaust systems.

- Material Properties : Flanges made of Inconel 600 can withstand thermal cycling and resist cracking under high stress.

Key Material Properties of Inconel 600

Inconel 600 stands out because of its unique combination of mechanical and chemical properties

- Corrosion Resistance : The alloy resists pitting and cracking caused by chloride ions and other harsh chemicals.

- Thermal Stability : Capable of withstanding temperatures ranging from cryogenic levels to over 2,000°F (1,093°C).

- Mechanical Strength : High tensile and yield strength ensures durability under mechanical stress.

- Oxidation Resistance : Chromium content prevents scaling and oxidation in high-temperature environments.

These Inconel 600 material properties make it indispensable for industries where reliability is paramount

Applications of Inconel 600 across Industries

- Chemical Processing: Inconel 600’s resistance to corrosive acids, alkalies, and oxidation makes it ideal for chemical reactors, distillation columns, and storage vessels.

- Aerospace : Its high strength-to-weight ratio and oxidation resistance ensure performance in jet engines, heat shields, and afterburners.

- Power Generation : The alloy’s stability under heat and stress is critical for steam turbines, nuclear reactors, and exhaust systems.

- Marine Engineering : Inconel 600’s saltwater corrosion resistance makes it a preferred choice for marine components like shafts, propellers, and fasteners.

- Food Processing : The alloy is used in heating elements and components exposed to high temperatures, such as bakery ovens and food sterilizers.

Why Choose Alloyed Sustainables LLP?

As a trusted Manufacturer, Supplier, and Stockist in Mumbai, India, Alloyed Sustainables LLP delivers high-quality Inconel Alloy 600 products. With a commitment to precision and reliability, the company offers various forms of Inconel 600 tailored to industry needs.

Key Benefits of Choosing Alloyed Sustainables LLP

- Strict adherence to ASTM standards.

- Customizable solutions to meet specific industrial demands.

- A vast inventory ensures prompt delivery.

Conclusion

Inconel 600’s versatility, robust material properties, and compliance with the Inconel 600 ASTM Standard make it a cornerstone for industries ranging from chemical processing to aerospace. Whether in the form of sheets, pipes, or wires, Inconel 600 proves to be an unmatched material for applications in harsh environments

For reliable and high-quality Inconel 600 material, trust Alloyed Sustainables LLP— your partner in excellence and innovation.