Grades

categories

Categories

enquire now

BARRED TEE

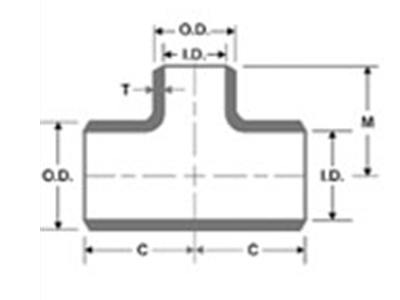

Alloyed Sustainables is a leading supplier and manufacturer of Barred Tees Butt Weld Fittings in a variety of dimensions. Our extensive experience in producing Barred Tees has enabled us to offer our clients a wide selection of Barred Tees in a variety of external diameters, types, production grades, and wall thicknesses, as well as other attributes. We offer our customers Barred Tees at competitive prices and manufacture our products in accordance with the requirements of our valued customers.

Description:

A barred tee, also known as a barred or a cross-over tee, is a type of pipe fitting used in pipelines to connect a branch line to the main line while providing a barrier or separation between the two flows. The key feature of a barred tee is a solid barrier or wall that separates the main run from the branch lines. At Alloyed Sustainables, we lead the way in producing a diverse range of Barred Tees. Our extensive selection covers various materials, sizes, and grades, meeting the unique needs of different industries.

Key features of Barred Tee:

- Fluid Separation: Barred Tees effectively prevent direct mixing of fluids by incorporating a solid barrier between the main and branch lines.

- Versatility: With diverse options in terms of sizes, materials, and grades, Barred Tees are adaptable and suitable for a wide range of industries and applications.

- Customization: The availability of various diameters and wall thicknesses ensures precise tailoring to specific project requirements.

- Precision Manufacturing: Barred Tees are manufactured to meet rigorous standards, ensuring reliable and consistent performance.

- Application Range: Barred Tees find their utility in scenarios where maintaining fluid separation and managing flow is critical.

Application across Industries:

- Oil and Gas: Barred Tees play a crucial role in separating different types of fluids such as oil, gas, and water, ensuring integrity in pipelines and preventing cross-contamination.

- Chemical Processing: Barred Tees are used to manage the flow of different chemicals within complex processing systems, preventing mixing and maintaining chemical stability.

- Power Generation: Barred Tees help manage different fluid streams in power plants, aiding in efficient energy generation while preventing undesired interactions.

- Water Treatment: These fittings find use in water treatment facilities to separate different water sources, maintaining the purity and quality of treated water.

- Marine: Barred Tees are used in marine applications to manage different fluids on ships and offshore platforms, contributing to safe operations and preventing marine pollution.

We provide Barred Tees made from a wide variety of materials and grades, intricately designed to fulfill the distinct requirements of our clients across a range of industries.

STAINLESS STEEL & DUPLEX STEEL BARRED TEE:

Specifications:

- Size: 1/2″ to 36NB”, ANSI/ASME B 16.9, MSS-SP-43

- Schedule: 10S/40S/80S/160S/XXS

- Stainless Steel : ASTM A 403 WP-TP 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel: ASTM A815- UNS S31803, S32750, S32760, S32205

ALLOY STEEL, CARBON STEEL & LTCS BARRED TEE:

Specifications:

- Size: 1/2″ to 36NB”, ANSI/ASME B 16.9

- Schedule: 10S/40S/80S/160S/XXS

- Alloy Steel: ASTM A 234 WPB, WP5,WP9,WP11,WP12,WP91

- Carbon Steel: ASTM A 234 WPB, IS 1239 PART II

- Low Temperature Carbon Steel: ASTM A-420 WPL6

- Other Services: Hot Dip Galvanizing, Sand Blasting

COPPER & NICKEL ALLOYS BARRED TEE:

Specifications:

- Size : 1/2″ to 36NB”, ANSI/ASME B 16.9

- Schedule: 10S/40S/80S

- Copper Nickel: C70600(90:10), C71500(70:30), C71640

- Nickel: UNS N02200, N02201

- Monel: UNS N04400

- Inconel: UNS N06600, N06601, N006625, N08800, N08810, N08825

- Hastelloy: UNS N10276, N06022, N10665, N06455

- SMO 254: UNS S31254

BARRED TEE

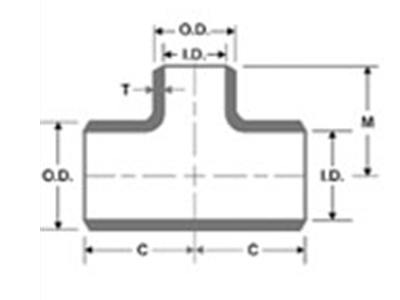

Alloyed Sustainables is a leading supplier and manufacturer of Barred Tees Butt Weld Fittings in a variety of dimensions. Our extensive experience in producing Barred Tees has enabled us to offer our clients a wide selection of Barred Tees in a variety of external diameters, types, production grades, and wall thicknesses, as well as other attributes. We offer our customers Barred Tees at competitive prices and manufacture our products in accordance with the requirements of our valued customers.

Description:

A barred tee, also known as a barred or a cross-over tee, is a type of pipe fitting used in pipelines to connect a branch line to the main line while providing a barrier or separation between the two flows. The key feature of a barred tee is a solid barrier or wall that separates the main run from the branch lines. At Alloyed Sustainables, we lead the way in producing a diverse range of Barred Tees. Our extensive selection covers various materials, sizes, and grades, meeting the unique needs of different industries.

Key features of Barred Tee:

- Fluid Separation: Barred Tees effectively prevent direct mixing of fluids by incorporating a solid barrier between the main and branch lines.

- Versatility: With diverse options in terms of sizes, materials, and grades, Barred Tees are adaptable and suitable for a wide range of industries and applications.

- Customization: The availability of various diameters and wall thicknesses ensures precise tailoring to specific project requirements.

- Precision Manufacturing: Barred Tees are manufactured to meet rigorous standards, ensuring reliable and consistent performance.

- Application Range: Barred Tees find their utility in scenarios where maintaining fluid separation and managing flow is critical.

Application across Industries:

- Oil and Gas: Barred Tees play a crucial role in separating different types of fluids such as oil, gas, and water, ensuring integrity in pipelines and preventing cross-contamination.

- Chemical Processing: Barred Tees are used to manage the flow of different chemicals within complex processing systems, preventing mixing and maintaining chemical stability.

- Power Generation: Barred Tees help manage different fluid streams in power plants, aiding in efficient energy generation while preventing undesired interactions.

- Water Treatment: These fittings find use in water treatment facilities to separate different water sources, maintaining the purity and quality of treated water.

- Marine: Barred Tees are used in marine applications to manage different fluids on ships and offshore platforms, contributing to safe operations and preventing marine pollution.

We provide Barred Tees made from a wide variety of materials and grades, intricately designed to fulfill the distinct requirements of our clients across a range of industries.

STAINLESS STEEL & DUPLEX STEEL BARRED TEE:

Specifications:

- Size: 1/2″ to 36NB”, ANSI/ASME B 16.9, MSS-SP-43

- Schedule: 10S/40S/80S/160S/XXS

- Stainless Steel : ASTM A 403 WP-TP 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel: ASTM A815- UNS S31803, S32750, S32760, S32205

ALLOY STEEL, CARBON STEEL & LTCS BARRED TEE:

Specifications:

- Size: 1/2″ to 36NB”, ANSI/ASME B 16.9

- Schedule: 10S/40S/80S/160S/XXS

- Alloy Steel: ASTM A 234 WPB, WP5,WP9,WP11,WP12,WP91

- Carbon Steel: ASTM A 234 WPB, IS 1239 PART II

- Low Temperature Carbon Steel: ASTM A-420 WPL6

- Other Services: Hot Dip Galvanizing, Sand Blasting

COPPER & NICKEL ALLOYS BARRED TEE:

Specifications:

- Size : 1/2″ to 36NB”, ANSI/ASME B 16.9

- Schedule: 10S/40S/80S

- Copper Nickel: C70600(90:10), C71500(70:30), C71640

- Nickel: UNS N02200, N02201

- Monel: UNS N04400

- Inconel: UNS N06600, N06601, N006625, N08800, N08810, N08825

- Hastelloy: UNS N10276, N06022, N10665, N06455

- SMO 254: UNS S31254