Grades

categories

Categories

enquire now

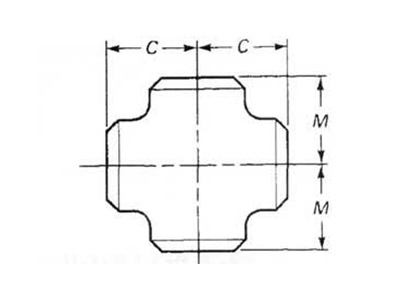

CROSS TEE

Alloyed Sustainables LLP excels as a provider, stockist, and exporter of an extensive range of high-quality Cross Tee fittings, offered at competitive prices. Our exceptional crosses are sought-after by a diverse clientele. Catering to unique requirements, we offer both customizable and standard designs of premium-grade crosses. Backed by profound industry expertise, we meticulously manufacture these crosses in adherence to global industry standards.

Description:

A cross tee butt weld fitting is a type of pipe fitting used in plumbing and piping systems to create a branch or intersection between four pipes. It has a cross-shaped design with one inlet and three outlets (or vice versa), forming a “plus” sign (+) configuration. This type of fitting allows the flow of fluids or gases to be redirected in multiple directions. Our Cross tees are available in a variety of materials, sizes and grades to satisfy the needs of clients and demanding industries.

Key Features of Cross Tees:

- Cross-Shaped Design: Cross tees have a cross-shaped layout with one inlet and three 90-degree outlets, enabling flow diversion in four directions.

- Branching Capability: They create branching points by channeling fluid or gas through the main inlet and distributing it via three outlets.

- Connection Types: Offered with different connection methods such as buttweld, socket weld, threaded, or flanged, adaptable to system needs.

- Pressure and Temperature Ratings: Engineered to withstand specific pressure and temperature conditions, ensuring safety under operational demands.

- Leak-Resistant: When installed correctly, cross tees provide secure and leak-resistant connections, vital for high-pressure applications.

Application across Industries:

- Chemical Processing: Cross tees play a role in chemical plants, allowing the distribution of different chemicals to multiple destinations within the processing setup.

- Oil and Gas: Within oil and gas pipelines, cross tees are used to divert and distribute oil, gas, or other fluids to different sections of the facility or to different pipelines.

- Water Treatment: Cross tees help manage water distribution and treatment processes in water treatment plants, directing water flow for filtration, purification, and distribution.

- Power Plants: Cross tees play a role in power generation facilities, helping distribute cooling fluids, steam, or other media to different parts of the plant.

- Marine and Shipbuilding: In marine applications, cross tees help distribute fluids on ships for various purposes, including propulsion and onboard systems.

Our portfolio comprises cross tees carefully manufactured from a variety of materials and grades to satisfy the demands of our clients in many sectors.

STAINLESS STEEL & DUPLEX STEEL CROSS TEES:

Specifications:

- Size : 1/2″ to 36NB”, ANSI/ASME B 16.9, MSS-SP-43

- Schedule : 10S/40S/80S/160S/XXS

- Stainless Steel : ASTM A 403 WP-TP 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A815- UNS S31803, S32750, S32760, S32205

ALLOY STEEL, CARBON STEEL & LTCS CROSS TEES:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S/160S/XXS

- Alloy Steel : ASTM A 234 WPB, WP5,WP9,WP11,WP12,WP91

- Carbon Steel : ASTM A 234 WPB, IS 1239 PART II

- Low Temperature Carbon Steel : ASTM A-420 WPL6

- Other Services : Hot Dip Galvanizing, Sand Blasting

COPPER & NICKEL ALLOYS CROSS TEES:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400

- Inconel : UNS N06600, N06601, N006625, N08800, N08810, N08825

- Hastelloy : UNS N10276, N06022, N10665, N06455

- SMO 254 : UNS S31254

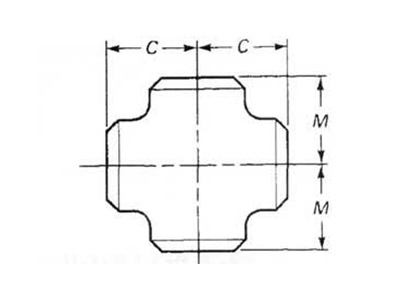

CROSS TEE

Alloyed Sustainables LLP excels as a provider, stockist, and exporter of an extensive range of high-quality Cross Tee fittings, offered at competitive prices. Our exceptional crosses are sought-after by a diverse clientele. Catering to unique requirements, we offer both customizable and standard designs of premium-grade crosses. Backed by profound industry expertise, we meticulously manufacture these crosses in adherence to global industry standards.

Description:

A cross tee butt weld fitting is a type of pipe fitting used in plumbing and piping systems to create a branch or intersection between four pipes. It has a cross-shaped design with one inlet and three outlets (or vice versa), forming a “plus” sign (+) configuration. This type of fitting allows the flow of fluids or gases to be redirected in multiple directions. Our Cross tees are available in a variety of materials, sizes and grades to satisfy the needs of clients and demanding industries.

Key Features of Cross Tees:

- Cross-Shaped Design: Cross tees have a cross-shaped layout with one inlet and three 90-degree outlets, enabling flow diversion in four directions.

- Branching Capability: They create branching points by channeling fluid or gas through the main inlet and distributing it via three outlets.

- Connection Types: Offered with different connection methods such as buttweld, socket weld, threaded, or flanged, adaptable to system needs.

- Pressure and Temperature Ratings: Engineered to withstand specific pressure and temperature conditions, ensuring safety under operational demands.

- Leak-Resistant: When installed correctly, cross tees provide secure and leak-resistant connections, vital for high-pressure applications.

Application across Industries:

- Chemical Processing: Cross tees play a role in chemical plants, allowing the distribution of different chemicals to multiple destinations within the processing setup.

- Oil and Gas: Within oil and gas pipelines, cross tees are used to divert and distribute oil, gas, or other fluids to different sections of the facility or to different pipelines.

- Water Treatment: Cross tees help manage water distribution and treatment processes in water treatment plants, directing water flow for filtration, purification, and distribution.

- Power Plants: Cross tees play a role in power generation facilities, helping distribute cooling fluids, steam, or other media to different parts of the plant.

- Marine and Shipbuilding: In marine applications, cross tees help distribute fluids on ships for various purposes, including propulsion and onboard systems.

Our portfolio comprises cross tees carefully manufactured from a variety of materials and grades to satisfy the demands of our clients in many sectors.

STAINLESS STEEL & DUPLEX STEEL CROSS TEES:

Specifications:

- Size : 1/2″ to 36NB”, ANSI/ASME B 16.9, MSS-SP-43

- Schedule : 10S/40S/80S/160S/XXS

- Stainless Steel : ASTM A 403 WP-TP 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A815- UNS S31803, S32750, S32760, S32205

ALLOY STEEL, CARBON STEEL & LTCS CROSS TEES:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S/160S/XXS

- Alloy Steel : ASTM A 234 WPB, WP5,WP9,WP11,WP12,WP91

- Carbon Steel : ASTM A 234 WPB, IS 1239 PART II

- Low Temperature Carbon Steel : ASTM A-420 WPL6

- Other Services : Hot Dip Galvanizing, Sand Blasting

COPPER & NICKEL ALLOYS CROSS TEES:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400

- Inconel : UNS N06600, N06601, N006625, N08800, N08810, N08825

- Hastelloy : UNS N10276, N06022, N10665, N06455

- SMO 254 : UNS S31254