Grades

categories

Categories

enquire now

END CAP

Alloyed Sustainables LLP has established itself as a reputable manufacturer and exporter of high-quality end caps. With a commitment to excellence, we provide a diverse selection of end caps that cater to various requirements across different industries. These end caps are manufactured in accordance with the national and international standards and can be tailored to fit specific needs, including dimensions, forms, outer diameters, thread sizes, materials, specifications and grades.

Description:

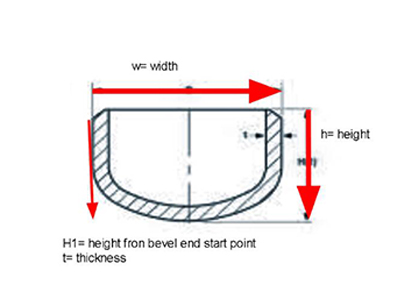

End caps are a type of butt weld fittings employed within piping systems to effectively seal the termination point of a pipe or tube. Through welding, these fittings are affixed onto pipes, establishing a reliable and impermeable connection. They find utility in scenarios where a pipeline needs no further extension or when temporary or permanent closure is required. The fabrication of end caps encompasses a range of materials to align with the specific demands of the given piping system, materials such as Stainless Steel, Carbon Steel, and Alloy Steel.

Key Features of End Caps:

- Customizable Specifications: End caps can be tailored to fit specific needs, including dimensions, forms, outer diameters, and thread sizes, ensuring an exact match for various applications.

- Sealing Functionality: Primarily designed to seal pipelines, end caps prevent fluid or gas leakage, maintaining the system’s integrity.

- Easy Installation: Installing end caps involve straightforward welding onto the pipe’s end, creating a leak-proof connection.

- Enhanced Piping System Integrity: By sealing the pipe end securely, end caps contribute to the overall safety and integrity of the system.

- Adaptability: End caps find use in both temporary and permanent applications, as project needs dictate.

Application across Industries:

- Renewable Energy: In renewable energy projects, end caps are used to seal pipes in solar thermal systems and geothermal installations.

- Power Generation: End caps are employed in power plants to seal pipes for various fluids, including cooling water and steam.

- Marine: In marine applications, end caps seal pipes on ships and offshore platforms, ensuring fluid containment in harsh environments.

- Water Treatment: End caps are applied in water treatment systems to seal pipes, ensuring the integrity of the treated water.

End Caps made from a variety of materials and grades are precisely tailored to fulfill the demands of our clients in a number of sectors.

STAINLESS STEEL & DUPLEX STEEL END CAPS:

Specifications:

- Size : 1/2″ to 36NB”, ANSI/ASME B 16.9, MSS-SP-43

- Schedule : 10S/40S/80S/160S/XXS

- Stainless Steel : ASTM A 403 WP-TP 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A815- UNS S31803, S32750, S32760, S32205

ALLOY STEEL, CARBON STEEL & LTCS END CAPS:

Specifications:

-

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S/160S/XXS

- Alloy Steel : ASTM A 234 WPB, WP5,WP9,WP11,WP12,WP91

- Carbon Steel : ASTM A 234 WPB, IS 1239 PART II

- Low Temperature Carbon Steel: ASTM A-420 WPL6

- Other Services : Hot Dip Galvanizing, Sand Blasting

COPPER & NICKEL ALLOYS END CAP:

Specifications:

END CAP

Alloyed Sustainables LLP has established itself as a reputable manufacturer and exporter of high-quality end caps. With a commitment to excellence, we provide a diverse selection of end caps that cater to various requirements across different industries. These end caps are manufactured in accordance with the national and international standards and can be tailored to fit specific needs, including dimensions, forms, outer diameters, thread sizes, materials, specifications and grades.

Description:

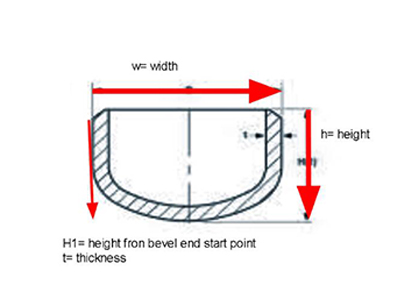

End caps are a type of butt weld fittings employed within piping systems to effectively seal the termination point of a pipe or tube. Through welding, these fittings are affixed onto pipes, establishing a reliable and impermeable connection. They find utility in scenarios where a pipeline needs no further extension or when temporary or permanent closure is required. The fabrication of end caps encompasses a range of materials to align with the specific demands of the given piping system, materials such as Stainless Steel, Carbon Steel, and Alloy Steel.

Key Features of End Caps:

- Customizable Specifications: End caps can be tailored to fit specific needs, including dimensions, forms, outer diameters, and thread sizes, ensuring an exact match for various applications.

- Sealing Functionality: Primarily designed to seal pipelines, end caps prevent fluid or gas leakage, maintaining the system’s integrity.

- Easy Installation: Installing end caps involve straightforward welding onto the pipe’s end, creating a leak-proof connection.

- Enhanced Piping System Integrity: By sealing the pipe end securely, end caps contribute to the overall safety and integrity of the system.

- Adaptability: End caps find use in both temporary and permanent applications, as project needs dictate.

Application across Industries:

- Renewable Energy: In renewable energy projects, end caps are used to seal pipes in solar thermal systems and geothermal installations.

- Power Generation: End caps are employed in power plants to seal pipes for various fluids, including cooling water and steam.

- Marine: In marine applications, end caps seal pipes on ships and offshore platforms, ensuring fluid containment in harsh environments.

- Water Treatment: End caps are applied in water treatment systems to seal pipes, ensuring the integrity of the treated water.

End Caps made from a variety of materials and grades are precisely tailored to fulfill the demands of our clients in a number of sectors.

STAINLESS STEEL & DUPLEX STEEL END CAPS:

Specifications:

- Size : 1/2″ to 36NB”, ANSI/ASME B 16.9, MSS-SP-43

- Schedule : 10S/40S/80S/160S/XXS

- Stainless Steel : ASTM A 403 WP-TP 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A815- UNS S31803, S32750, S32760, S32205

ALLOY STEEL, CARBON STEEL & LTCS END CAPS:

Specifications:

-

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S/160S/XXS

- Alloy Steel : ASTM A 234 WPB, WP5,WP9,WP11,WP12,WP91

- Carbon Steel : ASTM A 234 WPB, IS 1239 PART II

- Low Temperature Carbon Steel: ASTM A-420 WPL6

- Other Services : Hot Dip Galvanizing, Sand Blasting

COPPER & NICKEL ALLOYS END CAP:

Specifications: