Grades

categories

Categories

enquire now

SPECTACLE BLIND FLANGES

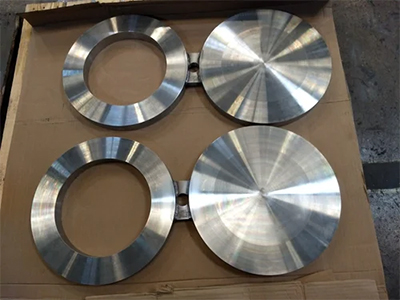

Alloyed Sustainables LLP is at the forefront of the Indian market as a prominent exporter and supplier of spectacle blind flanges. Our offerings come with cost-effective price tags. These flanges, known for their unique advantage of easy pipe connection without welding, find significant utility in specific scenarios. Characterized by a solid end and an open end connected by a tie-bar or web, spectacle blind flanges serve as pressure-retaining plates. Typically, the open end establishes a seal between two flanges, facilitating a continuous flow of fluids within the pipe system. Meanwhile, our range of Spectacle Blind Flanges is adaptable in terms of thickness, size, and specifications, catering precisely to our clients’ requirements.

Description:

Alloyed Sustainables LLP specializes in providing spectacle blind flanges, a specialized flange type utilized within piping systems for temporary flow blockage of fluids or gases. This facilitates visual inspections, maintenance, or repair activities without the need for complete pipeline disassembly. These flanges offer a versatile and efficient solution for isolating pipeline sections. The manufacturing of these spectacle blind flanges is executed using a certified metal forging technique endorsed by ASME A31.3, ASME B 16.48, and ASME B 16.5 standards. Their significance lies in effectively fitting various flanges onto chemical pipelines. It is imperative that these blinds adhere to the quality benchmarks set by ASTM B182 and ASTM SB 182. With size ranges spanning from 1/2″NB to 48″ NB, they can be customized to align with specific client prerequisites.

Key Features of Spectacle-Blind Flanges:

- Isolation and Blinding: Spectacle blinds effectively stop fluid or gas flow in pipelines, making them indispensable for maintenance and repair work without shutting down the entire system.

- Visual Verification: Operators can visually confirm whether the blinds are open or closed, ensuring proper isolation before beginning any work on the pipeline.

- Versatility: These flanges find applications across diverse industries, providing a solution for temporary isolation needs in various contexts.

- Safety Enhancement: Controlled isolation with spectacle blinds prevents accidental releases of hazardous substances, contributing to safer work environments.

- Easy Installation: Similar to standard flanges, spectacle blinds are straightforward to install, requiring bolting between pipeline sections.

Application across Industries:

- Oil and Gas: In the oil and gas industry, spectacle blinds are employed during maintenance and repairs of pipelines, allowing isolated sections to be worked on while the rest of the system remains operational.

- Petrochemical: Petrochemical facilities utilize spectacle blinds to isolate sections of pipelines carrying volatile substances, ensuring safe maintenance practices and preventing leaks.

- Chemical Processing: Spectacle blinds play a crucial role in chemical plants by allowing isolated access to pipeline segments for cleaning, inspection, and maintenance while minimizing production disruptions.

- Water Treatment: Water treatment plants use spectacle blinds to control the flow of liquids, facilitating routine inspections, repairs, and replacements of equipment.

- Power Generation: Power plants employ these flanges to isolate sections of piping systems for maintenance and repairs, enabling efficient servicing of critical components.

Our extensive range of Spectacle-Blind Flanges is meticulously crafted from a diverse array of materials and grades to cater to the requirements our valued clients and various industries.

STAINLESS STEEL & DUPLEX STEEL SPECTACLE-BLIND FLANGE:

Specifications:

- Size : 1/2″ NB to 48″ NB, ANSI/ASME B 16.5

- Standard : 150# , 300#, 600#, 900#, 1500#, 2500# in ASA 150 & ASA 300

- Stainless Steel : ASTM A 240 / 182 F – 304/

304H/ 304L/ 316/ 316H/ 316L/ 316Ti/ 309/ 310/ 317L/ 321/ 347/ 904L/Alloy 20 - Duplex steel : ASTM A 182 – F 51, F53, F55

ALLOY STEEL, CARBON STEEL & LTCS SPECTACLE-BLIND FLANGE:

Specifications:

- Size : 1/2″ NB to 48″ NB, ANSI/ASME B16.5

- Class : 150# , 300#, 600#, 900#, 1500#, 2500# in ASA 150 & ASA 300

- Alloy Steel : ASTM A 182 – F5, F9, F11, F12, F22 & F91

- Carbon Steel : ASTM A 105, ASTM A694, F42, F46, F52, F60, F65, F70

- Low Temperature Carbon Steel : A 350 LF2, A 516 GR. 70

COPPER & NICKEL ALLOYS SPECTACLE-BLIND FLANGE:

Specifications:

- Size : 1/2″NB to 6″ NB, ANSI/ASME B 16.5

- Standard : 150# , 300#, 600#, 900#, 1500#, 2500# in ASA 150 & ASA 300

- Copper Nickel : C70600(90: 10). C71500 (70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400

- lnconel : UNS N06600, N06601, N06625, N08800, N08810, N08825

- Hastelloy : UNS N10276, N06022, N10665, N06455

- Titanium Gr: 1,2,3 DTH 3.7025, DTH 3.7035, DTH 3.7055

- SMO 254: UNS S31254

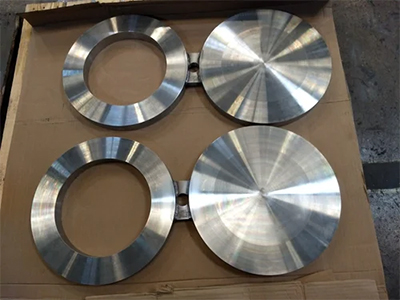

SPECTACLE BLIND FLANGES

Alloyed Sustainables LLP is at the forefront of the Indian market as a prominent exporter and supplier of spectacle blind flanges. Our offerings come with cost-effective price tags. These flanges, known for their unique advantage of easy pipe connection without welding, find significant utility in specific scenarios. Characterized by a solid end and an open end connected by a tie-bar or web, spectacle blind flanges serve as pressure-retaining plates. Typically, the open end establishes a seal between two flanges, facilitating a continuous flow of fluids within the pipe system. Meanwhile, our range of Spectacle Blind Flanges is adaptable in terms of thickness, size, and specifications, catering precisely to our clients’ requirements.

Description:

Alloyed Sustainables LLP specializes in providing spectacle blind flanges, a specialized flange type utilized within piping systems for temporary flow blockage of fluids or gases. This facilitates visual inspections, maintenance, or repair activities without the need for complete pipeline disassembly. These flanges offer a versatile and efficient solution for isolating pipeline sections. The manufacturing of these spectacle blind flanges is executed using a certified metal forging technique endorsed by ASME A31.3, ASME B 16.48, and ASME B 16.5 standards. Their significance lies in effectively fitting various flanges onto chemical pipelines. It is imperative that these blinds adhere to the quality benchmarks set by ASTM B182 and ASTM SB 182. With size ranges spanning from 1/2″NB to 48″ NB, they can be customized to align with specific client prerequisites.

Key Features of Spectacle-Blind Flanges:

- Isolation and Blinding: Spectacle blinds effectively stop fluid or gas flow in pipelines, making them indispensable for maintenance and repair work without shutting down the entire system.

- Visual Verification: Operators can visually confirm whether the blinds are open or closed, ensuring proper isolation before beginning any work on the pipeline.

- Versatility: These flanges find applications across diverse industries, providing a solution for temporary isolation needs in various contexts.

- Safety Enhancement: Controlled isolation with spectacle blinds prevents accidental releases of hazardous substances, contributing to safer work environments.

- Easy Installation: Similar to standard flanges, spectacle blinds are straightforward to install, requiring bolting between pipeline sections.

Application across Industries:

- Oil and Gas: In the oil and gas industry, spectacle blinds are employed during maintenance and repairs of pipelines, allowing isolated sections to be worked on while the rest of the system remains operational.

- Petrochemical: Petrochemical facilities utilize spectacle blinds to isolate sections of pipelines carrying volatile substances, ensuring safe maintenance practices and preventing leaks.

- Chemical Processing: Spectacle blinds play a crucial role in chemical plants by allowing isolated access to pipeline segments for cleaning, inspection, and maintenance while minimizing production disruptions.

- Water Treatment: Water treatment plants use spectacle blinds to control the flow of liquids, facilitating routine inspections, repairs, and replacements of equipment.

- Power Generation: Power plants employ these flanges to isolate sections of piping systems for maintenance and repairs, enabling efficient servicing of critical components.

Our extensive range of Spectacle-Blind Flanges is meticulously crafted from a diverse array of materials and grades to cater to the requirements our valued clients and various industries.

STAINLESS STEEL & DUPLEX STEEL SPECTACLE-BLIND FLANGE:

Specifications:

- Size : 1/2″ NB to 48″ NB, ANSI/ASME B 16.5

- Standard : 150# , 300#, 600#, 900#, 1500#, 2500# in ASA 150 & ASA 300

- Stainless Steel : ASTM A 240 / 182 F – 304/

304H/ 304L/ 316/ 316H/ 316L/ 316Ti/ 309/ 310/ 317L/ 321/ 347/ 904L/Alloy 20 - Duplex steel : ASTM A 182 – F 51, F53, F55

ALLOY STEEL, CARBON STEEL & LTCS SPECTACLE-BLIND FLANGE:

Specifications:

- Size : 1/2″ NB to 48″ NB, ANSI/ASME B16.5

- Class : 150# , 300#, 600#, 900#, 1500#, 2500# in ASA 150 & ASA 300

- Alloy Steel : ASTM A 182 – F5, F9, F11, F12, F22 & F91

- Carbon Steel : ASTM A 105, ASTM A694, F42, F46, F52, F60, F65, F70

- Low Temperature Carbon Steel : A 350 LF2, A 516 GR. 70

COPPER & NICKEL ALLOYS SPECTACLE-BLIND FLANGE:

Specifications:

- Size : 1/2″NB to 6″ NB, ANSI/ASME B 16.5

- Standard : 150# , 300#, 600#, 900#, 1500#, 2500# in ASA 150 & ASA 300

- Copper Nickel : C70600(90: 10). C71500 (70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400

- lnconel : UNS N06600, N06601, N06625, N08800, N08810, N08825

- Hastelloy : UNS N10276, N06022, N10665, N06455

- Titanium Gr: 1,2,3 DTH 3.7025, DTH 3.7035, DTH 3.7055

- SMO 254: UNS S31254