Marine engineering presents unique challenges due to the harsh and corrosive environment of seawater. Traditional materials often fail under these conditions, leading to the need for specialized alloys. Monel 400 wire has emerged as a crucial material in this sector, offering superior performance and durability. This blog explores the vital role that Monel 400 plays in marine engineering and why it is a preferred choice for various applications

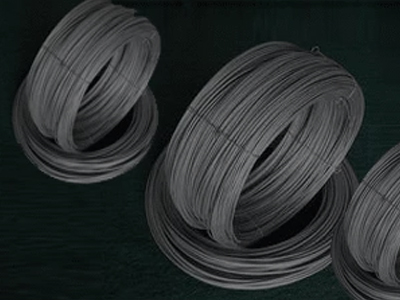

Understanding Monel 400

Monel 400 consists of approximately 67% nickel and 23% copper, with small amounts of iron, manganese, carbon, and silicon. This composition provides it with excellent corrosion resistance, high strength, and good weldability, making it suitable for use in extreme environments. The alloy was first developed by the International Nickel Company (INCO) and has since become a standard in industries requiring robust, corrosion-resistant materials

Properties of Monel 400

The properties of Monel 400 make that makes it ideal for marine applications are as follows

- Corrosion Resistance : One of the primary reasons for using Monel 400 wire in marine environments is its outstanding resistance to seawater and brine. It withstands the corrosive effects of saltwater, making it ideal for underwater and coastal installations.

- High Strength : Monel 400 maintains its strength even at sub-zero temperatures, which is crucial for marine applications that require materials to perform reliably under varying temperature conditions.

- Durability : The alloy’s resistance to biofouling and pitting further enhances its durability, reducing maintenance costs and downtime.

- Good Weldability and Fabricability : Monel 400 wire can be easily welded and fabricated, allowing for versatile application in complex marine structures and machinery.

Applications of Monel 400 Wire in Marine Engineering

- Shipbuilding :

Monel 400 wire is extensively used in shipbuilding for various purposes, including:- Piping Systems : The wire is used to create durable piping systems that transport seawater for cooling and other processes. Its corrosion resistance ensures long-term reliability.

- Pump Shafts and Propellers : The strength and resistance of Monel 400 make it suitable for critical components like pump shafts and propellers, which are constantly exposed to seawater.

- Offshore Oil and Gas :

In offshore oil and gas platforms, Monel 400 wire is used in:- Drilling Equipment : Components such as drill collars and flexible piping benefit from the alloy’s durability and resistance to seawater corrosion.

- Subsea Systems : Subsea valves, connectors, and other critical components are often made from Monel 400 to ensure they can withstand the harsh underwater environment.

- Marine Fasteners :

Monel 400 wire is used to manufacture bolts, screws, and other fasteners for marine applications. These fasteners provide the necessary strength and corrosion resistance required to hold marine structures together securely.

- Desalination Plants :

In desalination plants, Monel 400 wire is used in:- Heat Exchangers : The alloy’s thermal conductivity and resistance to corrosion make it ideal for heat exchangers, which are essential in the desalination process.

- Pumps and Valves : Reliable operation of pumps and valves in desalination plants is crucial, and Monel 400 ensures these components can handle the corrosive nature of seawater.

The Importance of a Reliable Monel 400 Wire Supplier

Given the critical role of Monel 400 wire in marine engineering, it is essential to source it from a reputable Monel 400 wire supplier. A reliable supplier ensures

- Quality Assurance : High-quality Monel 400 wire that meets industry standards and specifications.

- Consistency : Consistent material properties across different batches, ensuring uniform performance in all applications.

- Availability : Timely delivery and sufficient stock to meet project requirements without delays.

Alloyed Sustainables: Your Trusted Monel 400 Wire Supplier

At Alloyed Sustainables, we understand the demands of marine engineering and are committed to providing top-grade Monel 400 wire. Our extensive inventory, stringent quality control processes, and expert team ensure that you receive the best material for your applications. Whether you need Monel 400 wire for shipbuilding, offshore oil and gas, marine fasteners, or desalination plants, Alloyed Sustainables is your go-to Monel 400 wire supplier

Conclusion

The marine engineering industry relies heavily on materials that can withstand the corrosive and demanding marine environment. Monel 400 wire has proven to be an indispensable material, offering unmatched corrosion resistance, strength, and durability. By choosing a reliable Monel 400 wire supplier like Alloyed Sustainables, you ensure the success and longevity of your marine projects. Embrace the power of Monel 400 and sail confidently into the future

Contact us Alloyed Sustainables today at sales@alloyedsustainable.com to explore our wide range of Monel Wire 400 and explore how we can help you optimize your projects with superior materials