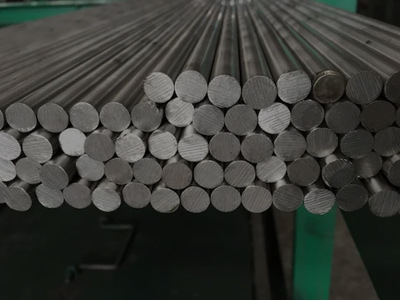

Stainless steel is renowned for its robustness and versatility, which are vital in various high-demand environments. Among its many grades, stainless steel 310 has carved a niche due to its high heat resistance and strength. Stainless steel 310 round bars are particularly celebrated for their durability and are extensively used across multiple sectors. Let’s delve into the five key industries that benefit significantly from ss 310 round bars

1. Energy Production

Energy production facilities, especially those involving high temperatures and pressures, require materials that can withstand harsh conditions. Stainless steel 310 round bars are utilized for their exceptional performance in thermal environments. These bars are integral components in parts like boiler supports, combustion chambers, and burners, where ordinary steel might succumb to extreme heat. The ability of ss 310 round bars to maintain structural integrity at temperatures up to 2100°F (1150°C) is particularly valuable. This feature ensures that the energy production processes are safe and efficient, minimizing downtime due to material failure

2. Petrochemical Industry

The petrochemical sector demands materials that can endure chemical exposure and thermal stress simultaneously. Stainless steel 310 round bars are up to the task, thanks to their impressive corrosion resistance and strength at high temperatures. These properties are critical for components like reactors and storage tanks, which are exposed to corrosive substances and variable temperatures. ss 310 round bars adhere to ASTM A276 standards, ensuring reliability and performance in these challenging environments. The alloy’s composition includes high levels of chromium and nickel, which not only help in resisting corrosion but also enhance the material’s overall durability and longevity

3. Aerospace

Aerospace applications require materials that can perform under extreme conditions. Stainless steel 310 round bars are used in the manufacture of engine parts and exhaust systems that need to withstand high temperatures during flights. The aerospace industry benefits from the alloy’s ability to resist scaling and maintain its strength even under high thermal stress. This reliability is crucial for the safety and performance of aerospace components, contributing significantly to the industry’s ability to meet rigorous safety standards

4. Food Processing and Equipment

Hygiene and thermal resistance are paramount in the food processing industry. Stainless steel 310 round bars are preferred for applications involving ovens, fryers, and other food preparation equipment that operate at high temperatures. The non-reactive nature of ss 310 round bars ensures that there is no contamination of the food being processed, which is essential for maintaining food safety. Additionally, the ease of cleaning and the material’s resistance to oxidation at high temperatures help maintain stringent hygiene standards required in food production environments

5. Heat Treatment Facilities

Heat treatment processes involve cyclic heating and cooling to alter the physical properties of metals. Stainless steel 310 round bars are extensively used in creating fixtures, baskets, and trays that undergo these treatment processes. The material’s high melting point and robustness at elevated temperatures ensure that it can endure the rigorous conditions of heat treatment facilities without deforming or failing. This durability is critical for maintaining the precision and quality of the heat-treating processes, thereby ensuring the production of high-quality metal products

Conclusion

Stainless steel 310 round bars play a pivotal role in industries that operate under extreme conditions. Their ability to withstand high temperatures and resist corrosion makes them an indispensable material in energy production, petrochemicals, aerospace, food processing, and heat treatment facilities. The adherence to ASTM A276 standards highlights their reliability and efficacy in critical applications. As industries continue to evolve and face new challenges, stainless steel 310 round bars will remain a key component in driving innovation and enhancing operational efficiencies. This exploration underscores the material’s significance in modern industrial applications and its contribution to advancing technology and safety in various sectors

You can Contact Alloyed Sustainables today at sales@alloyedsustainable.com to explore more about our Stainless Steel 310 Round Bars and how we can help you to implement them in your systems.