Perforated sheets are widely used in many sectors due to their characteristics of high strength, beauty, and practicality. In architecture, engineering, and manufacturing industries, perforated sheets are very useful due to the following advantages. In this blog, you will understand what perforated sheets are, the different types of perforated sheets, how they are made, and their applications. When you consider these factors, you will be in a position to realize why perforated sheets are used in many applications

Types of Perforated Sheets

There are several types of perforated sheets available, each designed to meet specific requirements

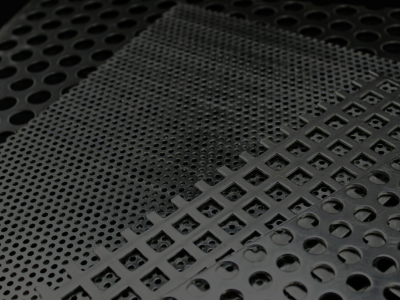

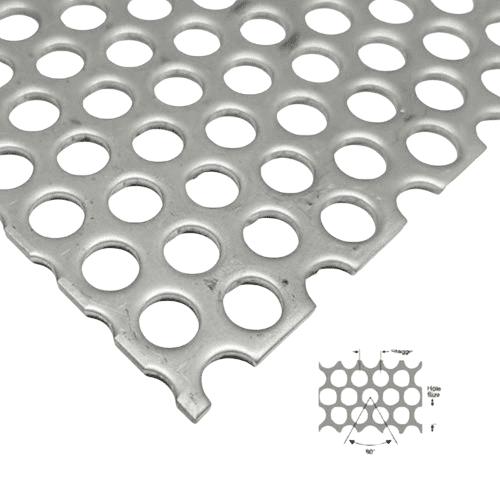

- Perforated Metal Sheet :

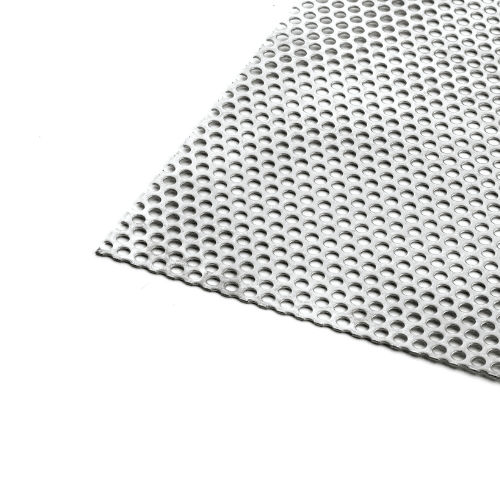

perforated metal sheet can be made of different types of metal which are aluminum, brass, copper and steel among others. These sheets find application in construction, automobiles and industries mainly because of their toughness and strength. The sheets of the metal can be drilled or punched in different pattern and sizes depending on the client’s requirements. - Stainless Steel Perforated Sheet :

stainless steel perforated sheet is appreciated due to the material’s relative inability to rust and the sheet’s overall durability. This kind of perforated sheet is suitable for use in areas that are exposed to moisture, chemicals or high/low temperatures. Stainless steel perforated sheets are used in most of the architectural designs, food processing equipment, and filtration systems. - Perforated Plastic Sheet :

perforated plastic sheet is easy to handle and use and does not react with chemicals and is not affected by Ultra-violet light. These sheets are widely used in such sectors as agricultural, chemical, and electrical industries. Perforated plastic sheets can be made from polyethylene, polypropylene and PVC but each material has its own characteristics that make it fit for a certain use.

Manufacturing Processes

The manufacturing process of perforated sheets involves several steps to ensure precision and quality. Here’s an overview of how these sheets are made

- Material Selection :

The first step is the choice of the material depending on the characteristics that should be provided by the final product. Steels, aluminiums, coppers or polyethylenes, PVCs are selected based on the application considerations. - Sheet Preparation :

The selected material is then sawn into sheets of the desired dimensions and thickness. This stage makes sure that the sheets are prepared for the perforation process to be conducted. - Perforation :

Perforation is done using various methods such as punching, drilling, or laser cutting. The choice of method depends on the material type, hole size, and pattern. Punching involves mechanically pressing holes into the sheet, while laser cutting uses focused light to create precise holes. - Finishing :

After perforation, the sheets undergo finishing processes to remove any burrs or sharp edges. This step ensures the sheets are safe to handle and meet quality standards. Finishing processes can include deburring, polishing, or coating, depending on the material and application

.

Applications of Perforated Sheets

Perforated sheets are used in a wide range of applications due to their versatility and functionality. Here are some common uses

- Architectural and Design :

In architecture, perforated sheets are used for decorative purposes, providing a modern and aesthetic appeal to buildings. They can be used for facades, sunshades, and interior design elements, offering both beauty and functionality. - Industrial and Manufacturing :

In industrial settings, perforated metal sheets are used for filtration, separation, and ventilation. They are commonly found in machinery guards, conveyor belts, and protective screens. Their durability and strength make them suitable for demanding environments. - Automotive :

Perforated sheets are used in the automotive industry for components like grilles, exhaust systems, and heat shields. The perforations help in reducing weight while maintaining structural integrity and allowing for proper ventilation. - Agricultural :

In agriculture, perforated plastic sheets are used for applications like grain drying, seed sorting, and greenhouse ventilation. Their lightweight and chemical-resistant properties make them ideal for these uses. - Electronics :

Perforated sheets are also used in the electronics industry for components such as speaker grilles, ventilation panels, and protective covers. The perforations provide necessary airflow while protecting delicate electronic components

.

Advantages of Perforated Sheets

Perforated sheets offer several advantages that make them a preferred choice in many industries

- Versatility :

The ability to customize hole sizes, shapes, and patterns makes perforated sheets highly versatile. They can be tailored to meet specific requirements, ensuring optimal performance in various applications. - Durability :

Perforated metal sheets, especially those made from stainless steel, offer exceptional durability and resistance to wear and tear. This makes them suitable for demanding environments where longevity is essential. - Aesthetic Appeal :

The unique patterns and designs available with perforated sheets add aesthetic value to architectural and design projects. They offer a modern and sophisticated look while serving practical purposes. - Improved Ventilation and Filtration :

The holes in perforated sheets allow for improved airflow and filtration, making them ideal for applications where ventilation or separation is required. This is particularly important in industries like HVAC, automotive, and agriculture

.

Conclusion

Perforated sheets are an integral part of various industries due to their unique combination of strength, functionality, and aesthetic appeal. Whether used in architecture, industrial manufacturing, or automotive applications, these sheets offer numerous advantages that make them indispensable. By understanding the types, manufacturing processes, and applications of perforated sheets, you can appreciate their value and versatility in modern projects

You can Contact Alloyed Sustainables today at sales@alloyedsustainable.com to learn more about our perforated sheets and how you can implement them in your projects.