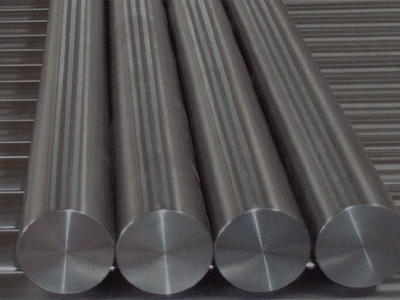

Stainless steel is an essential part of modern industry, known for its strength, corrosion resistance, and wide range of alloys. Round bar is one of the most versatile types of stainless steel, used for anything from construction to precision manufacturing. Alloyed Sustainables is a leading Stainless Steel 310 round bar supplier. This grade, often known as stainless 310, has excellent high-temperature performance and oxidation resistance, making it ideal for demanding applications in a variety of sectors. Let’s find out what makes a 310 stainless steel round bar so desirable

Understanding Stainless Steel 310

Austenitic stainless steels include Stainless Steel 310 and the nearly related 310S grade. This relates to its unique crystal structure, which provides both strength and ductility. Stainless steel 310’s feature is its high chromium and nickel content. Chromium is extremely resistant to high temperatures and oxidation (rusting). Nickel increases its hardness and capacity to endure corrosive situations. These characteristics make Stainless Steel 310 round bar an excellent choice for projects where components will be exposed to high temperatures, oxidation dangers, or harsh chemicals

How Stainless Steel 310 Round Bar is Made

- Raw Materials : The process of manufacturing of Stainless Steel 310 round bar begins with the careful selection of raw materials. Scrap stainless steel serves as a sustainable base, with exact amounts of chromium, nickel, and other alloying materials added to create the grade’s unique qualities.

- Melting and Refining : These raw materials are fused in high-temperature furnaces, often electric arc furnaces. To assure the quality and consistency of the finished product, the melt composition must be carefully controlled and contaminants removed during this stage.

- Casting : The molten steel is then poured into molds, typically forming large ingots or other intermediate shapes. The solidification process during this stage influences the steel’s initial grain structure.

- Hot Working : Ingots undergo processes like hot rolling or forging. These processes involve applying heat and force to reshape the steel into round bars of the desired dimensions. Hot working refines the grain structure, improving the bar’s mechanical properties.

- Finishing : Depending on the application, the round bar may receive additional treatments. Heat treatments can alter the steel’s hardness, strength, or ductility. Machining can create precise shapes or features, and surface finishes can be applied for aesthetics or enhanced corrosion resistance

.

Surface Finishes of Stainless Steel 310 Round Bar

Some of the surface finishes are mentioned below :

- Hot Rolled : The raw form of the bar, where the steel is shaped at high temperatures. This finish exhibits a rough, scaled surface, ideal for further processing but not commonly used in its ‘as is’ state.

- Annealed and Pickled : This two-step process produces a more uniform and smoother finish than hot-rolled. Annealing softens the steel, and pickling removes surface oxides, giving it a subtly matte appearance. This finish offers improved functional properties and is common for a wide range of applications.

- Cold Drawn : Here, the bar is pulled through a die at room temperature, resulting in enhanced dimensional accuracy and surface smoothness. This finish is often used for precision components or where a brighter appearance is needed.

- Polished : Various polishing techniques bring an increasingly lustrous appearance to stainless steel 310 bars. From a smooth satin finish (sometimes called No.4) to a highly reflective mirror polish, polished bars can serve both functional and aesthetic purposes.

- Centreless Ground : Produces excellent dimensional precision and a nearly flawless surface. Ideal for components demanding tight tolerances and smooth operation.

- Rough Turned : Achieved on a lathe, rough turning removes a layer of material for a slightly smoother surface than hot-rolled with tighter dimensional control.

Benefits of Using Stainless Steel 310 Round Bar

- Long Service Life : Stainless Steel 310 round bar’s impressive resistance to heat, oxidation, and corrosion translates directly into a long lifespan. Components made from this material can withstand harsh environments and demanding conditions for extended periods. This reduces the frequency of replacements and minimizes downtime due to failures, ultimately leading to significant cost savings.

- Low Maintenance : The inherent properties of Stainless Steel 310 round bar mean it requires minimal upkeep. Its resistance to corrosion and surface degradation reduces the need for frequent cleaning, repairs, or protective coatings. This translates to savings in both labor hours and the cost of maintenance materials.

- Versatility : Stainless Steel 310 round bar is exceptionally versatile due to its combination of strength, formability, and resistance to harsh environments. It finds applications across industries ranging from power generation to chemical processing. This versatility makes it a valuable material for engineers and manufacturers, as it can solve diverse challenges in multiple sectors

.

Specifications and Grades

We provide Stainless Steel 310 round bar in a range of sizes to suit diverse project requirements. This flexibility allows you to choose the right diameter and length for your specific needs

Industry Standards (ASTM A276 and ASME SA479): Adherence to these standards ensures the round bar meets rigorous specifications for chemical composition, mechanical properties, and dimensional tolerances. This guarantees consistent quality and reliable performance across different batches of material

By offering various sizes and ensuring compliance with industry standards, Alloyed Sustainables provides both convenience and peace of mind. You can readily find the correct dimensions of Stainless Steel 310 round bar for your application and trust that it possesses the mechanical properties you need for a successful project

Maintenance and Care for Stainless Steel 310 Round Bar

While the stainless steel 310 round bar is well known for its durability, taking proper care ensures it maintains its superior properties and appearance throughout its lifespan. Here are some key points

- Routine Cleaning : Even with its natural corrosion resistance, regular cleaning is beneficial for 310 stainless steel round bars. This prevents the buildup of dirt, grime and potential contaminants that could affect its long-term performance

- Warm water and a mild detergent are often sufficient

- For more stubborn dirt, non-abrasive cleaning solutions specifically designed for stainless steel can be used

- Avoiding Abrasives : Abrasive cleaners or tools like steel wool can scratch the surface of stainless steel 310, affecting its appearance and potentially creating areas more susceptible to corrosion. Use soft clothes and sponges whenever possible.

- Addressing Scratches : If minor scratches do occur, specialized stainless steel polishing compounds can help restore the original finish.

- Environmental Considerations : Though stainless 310 is resistant to many harsh conditions, it’s wise to be mindful of its intended environment

- Very high levels of chlorides (like seawater) can still pose a risk, so extra cleaning may be needed for applications like marine environments

- Prolonged exposure to extreme temperatures could affect certain surface finishes. Consult your supplier for guidance if this is a concern

Alloyed Sustainables: Your Source for Stainless Steel 310 Round Bar

Alloyed Saustainables LLP understands the importance of precision and performance when it comes to your projects. Contact us at sales@alloyedsustainable.com to discuss how our Stainless Steel 310 round bar can meet your demanding industrial needs