The world of machinery is a dynamic one that is constantly developing due to the process of invention and optimization. There is nothing more central to many mechanical systems than hydraulic pipes. These elements are the critical building blocks of hydraulic systems, which are used in the proper functioning of numerous machines. This blog post explores the use of hydraulic pipes in the machinery industry especially the use of alloyed materials in sustainable manner

The Fundamentals of Hydraulic Systems

Inconel 800HT is an alloy of nickel, iron and chromium that has high strength and is highly resistant to high temperature oxidation and carburization. This alloy, known as Inconel 800 material, is an enhancement of the Inconel 800 and 800H materials with better performance at high temperatures over a long period

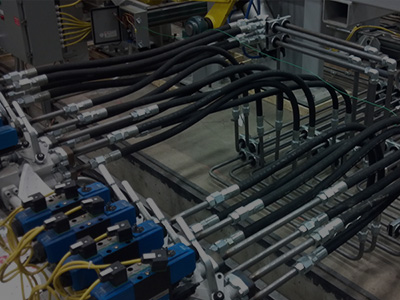

Hydraulic systems operate on a simple principle of fluid in the transfer of power. It is used when a force is to be applied at one point and transmitted through an incompressible fluid, usually oil to another point. This fluid power is then used to do work which may entail lifting, pushing, pulling or rotating of various parts. Hydraulic tubes and pipes are essential in this process as they convey the hydraulic fluid from one part of the system to another

The Role of Hydraulic Pipes

Hydraulic pipes are the blood vessels of hydraulic systems through which hydraulic fluid is transported from one component of the machinery to another. They are made to be high pressure resistant so that the fluid is allowed to pass through without interruption or leakage. These pipes cannot be overemphasized since any failure could result to system shut down, expensive repair and sometimes even dangerous

Applications in Machinery

Hydraulic systems are ubiquitous in various fields of machinery. Here are some notable applications

- Construction Machinery :

In construction, the equipment such as the excavators, bulldozers, and cranes are mainly operated by hydraulic systems. Hydraulic pipes and hoses are connected by hydraulic pipe fittings to transfer the fluid to hydraulic cylinders that operate the movement of the arms and booms of the machine. Hydraulic systems are useful due to the fine control they provide for operating loads and performing delicate operations. - Agricultural Equipment :

Tractors, harvesters and other agricultural equipments employ hydraulic system for operations such as lifting, lowering and adjusting of implements. Hyd pipes assist these machines in doing the following tasks; tilling, planting, weeding, harvesting among others. Hydraulic systems are very flexible and reliable which are the reasons why they are used in the modern agriculture. - Industrial Machinery :

Hydraulic systems are used to operate presses, injection moulding machines and conveyors in factories and manufacturing plants. Hydraulic pipes and tubes make sure that these systems run efficiently, delivering the force required in operations such as stamping, moulding, and moving materials. Hydraulic systems are efficient in their operations and this leads to increased production and less costs. - Automotive Industry :

Hydraulics are used in the automotive industry in manufacturing and also in maintenance of vehicles. Hydraulic lifts for instance are used in car repair shops to lift cars for inspection and repair purposes. Hydraulic pipe fittings are used in the braking system of vehicles; they transfer the force exerted by the brake pedal to the brake calipers thereby enabling the braking system to work effectively

.

Hydraulic Technology in Machinery

- Excavators :

Excavators rely on hydraulic systems for their powerful and precise movements. The hydraulic pipes transport the fluid to the hydraulic cylinders, enabling the excavator to dig, lift, and move heavy materials efficiently. - Loaders :

Loaders use hydraulics to raise and lower their buckets. The hydraulic pipes and tubes ensure smooth operation, allowing the loader to perform tasks like moving soil, debris, and other materials with ease. - Cranes :

Cranes are dependent on hydraulic systems for lifting and moving heavy loads. Hydraulic pipes and fittings are crucial in these systems, providing the necessary force to operate the crane’s boom and winch mechanisms. - JCB Machines :

JCB (Joseph Cyril Bamford) machines, including backhoes and loaders, utilise hydraulic systems for their versatile operations. The hydraulic pipes enable these machines to perform various tasks, such as excavation, material handling, and demolition

.

Basic Working Principle of Hydraulic Pipes

The working principle of hydraulic pipes involves the transmission of fluid power. Here is a simplified explanation

- Hydraulic Pump : The hydraulic system begins with a hydraulic pump, which converts mechanical energy into hydraulic energy by pressurising the hydraulic fluid.

- Hydraulic Pipes and Tubes : The pressurised fluid is then transported through hydraulic pipes and tubes to various components of the machinery.

- Control Valves : Control valves regulate the flow of hydraulic fluid, directing it to the desired actuator (such as hydraulic cylinders or motors).

- Hydraulic Actuators : The hydraulic fluid reaches the actuators, which convert the hydraulic energy back into mechanical energy, performing the required task (lifting, pushing, rotating, etc.).

- Return Line : After performing the work, the hydraulic fluid returns to the reservoir through return lines, completing the cycle.

The Importance of Sustainability

With the increasing concerns for environmental conservation, the materials used in hydraulic systems are also changing. Alloyed materials are becoming more popular because of their strength, durability, and relative friendliness to the environment. Alloyed hydraulic pipes are made to be very durable in order to be able to be used in harsh environments and thus not require constant replacement and repair. This longevity means that there is less waste and the use of resources is optimized

Conclusion

The application of hydraulic pipes in the field of machinery is vast and varied. From construction and agriculture to industrial and automotive sectors, hydraulic systems play a pivotal role in modern mechanical operations. As we move towards a more sustainable future, the use of alloyed materials in hydraulic pipes and fittings is becoming increasingly important. These materials not only enhance the performance and reliability of hydraulic systems but also contribute to environmental sustainability

You can Contact Alloyed Sustainables today at sales@alloyedsustainable.com to learn more about our Hydraulic Pipes and how you can use them in machineries.