Grades

categories

Categories

enquire now

BARREL NIPPLES

Alloyed Sustainables LLP is a reputable manufacturer of barrel nipples. With an unwavering commitment, we adhere rigorously to both domestic and international quality standards, ensuring that each product that bears our name is a testament to excellence and reliability. We manufacture barrel nipples in a range of Specifications, Sizes, Materials and Grades to meet the distinct needs of our customers and various industries.

Description:

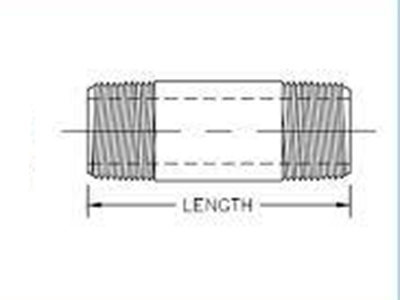

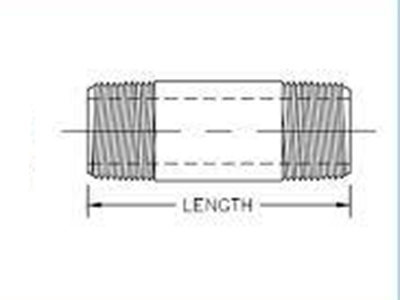

A barrel nipple is a short piece of pipe typically threaded at both ends. It’s often used to connect two fittings or pipes together in a plumbing system. These fittings are threaded on both ends, allowing them to be screwed into other threaded fittings or pipes, creating a secure connection. Barrel nipples come in various lengths and diameters, and they are frequently used in piping systems to extend or connect pipes, especially in tight spaces or when a particular configuration is required. These Barrel Nipples are available in multiple materials such as Stainless Steel, Nickel, Monel, Inconel, Hastelloy, Duplex, Carbon and LTCS, etc.

Key Features of Barrel Nipples:

- Compact Connection: Barrel nipples are short pipe sections with threaded ends on both sides, making them perfect for connecting two components in confined spaces.

- Material Diversity: Available in various materials like stainless steel and brass, barrel nipples offer adaptability for different applications and fluids.

- Threaded Versatility: Featuring male threads on both ends, these nipples are versatile connectors compatible with various threaded fittings.

- Pressure Compatibility: Their pressure handling capacity depends on material and design, ensuring proper selection for specific pressure requirements.

- Corrosion Considerations: Depending on material, barrel nipples can resist corrosion, crucial for durability in corrosive environments.

- Leak Prevention: Using thread sealant tape or pipe dope during installation helps prevent leakage at threaded connections.

Application across Industries:

- Oil and Gas: They play a role in transporting fluids within oil and gas pipelines, both in exploration and distribution processes.

- Chemical Processing: Barrel nipples with corrosion-resistant materials are crucial for conveying chemicals safely within processing plants.

- HVAC (Heating, Ventilation, and Air Conditioning): Barrel nipples help connect pipes in HVAC systems, ensuring efficient heating and cooling distribution.

- Marine: Barrel nipples are valuable in marine environments for connecting pipes and fittings on ships and offshore structures.

We offer Barrel Nipples crafted from a wide array of materials and grades, intricately designed to meet the specific requirements of our clients spanning various industries.

STAINLESS STEEL & DUPLEX STEEL BARREL NIPPLES:

Specifications:

- Size : 1/2″ to 36NB”, ANSI/ASME B 16.9, MSS-SP-43

- Schedule : 10S/40S/80S/160S/XXS

- Stainless Steel : ASTM A 403 WP-TP 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A815- UNS S31803, S32750, S32760, S32205

ALLOY STEEL, CARBON STEEL & LTCS BARREL NIPPLES:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S/160S/XXS

- Alloy Steel : ASTM A 234 WPB, WP5,WP9,WP11,WP12,WP91

- Carbon Steel : ASTM A 234 WPB, IS 1239 PART II

- Low Temperature Carbon Steel : ASTM A-420 WPL6

- Other Services : Hot Dip Galvanizing, Sand Blasting

COPPER & NICKEL ALLOYS BARREL NIPPLES:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400

- Inconel : UNS N06600, N06601, N006625, N08800, N08810, N08825

- Hastelloy : UNS N10276, N06022, N10665, N06455

- SMO 254: UNS S31254

BARREL NIPPLES

Alloyed Sustainables LLP is a reputable manufacturer of barrel nipples. With an unwavering commitment, we adhere rigorously to both domestic and international quality standards, ensuring that each product that bears our name is a testament to excellence and reliability. We manufacture barrel nipples in a range of Specifications, Sizes, Materials and Grades to meet the distinct needs of our customers and various industries.

Description:

A barrel nipple is a short piece of pipe typically threaded at both ends. It’s often used to connect two fittings or pipes together in a plumbing system. These fittings are threaded on both ends, allowing them to be screwed into other threaded fittings or pipes, creating a secure connection. Barrel nipples come in various lengths and diameters, and they are frequently used in piping systems to extend or connect pipes, especially in tight spaces or when a particular configuration is required. These Barrel Nipples are available in multiple materials such as Stainless Steel, Nickel, Monel, Inconel, Hastelloy, Duplex, Carbon and LTCS, etc.

Key Features of Barrel Nipples:

- Compact Connection: Barrel nipples are short pipe sections with threaded ends on both sides, making them perfect for connecting two components in confined spaces.

- Material Diversity: Available in various materials like stainless steel and brass, barrel nipples offer adaptability for different applications and fluids.

- Threaded Versatility: Featuring male threads on both ends, these nipples are versatile connectors compatible with various threaded fittings.

- Pressure Compatibility: Their pressure handling capacity depends on material and design, ensuring proper selection for specific pressure requirements.

- Corrosion Considerations: Depending on material, barrel nipples can resist corrosion, crucial for durability in corrosive environments.

- Leak Prevention: Using thread sealant tape or pipe dope during installation helps prevent leakage at threaded connections.

Application across Industries:

- Oil and Gas: They play a role in transporting fluids within oil and gas pipelines, both in exploration and distribution processes.

- Chemical Processing: Barrel nipples with corrosion-resistant materials are crucial for conveying chemicals safely within processing plants.

- HVAC (Heating, Ventilation, and Air Conditioning): Barrel nipples help connect pipes in HVAC systems, ensuring efficient heating and cooling distribution.

- Marine: Barrel nipples are valuable in marine environments for connecting pipes and fittings on ships and offshore structures.

We offer Barrel Nipples crafted from a wide array of materials and grades, intricately designed to meet the specific requirements of our clients spanning various industries.

STAINLESS STEEL & DUPLEX STEEL BARREL NIPPLES:

Specifications:

- Size : 1/2″ to 36NB”, ANSI/ASME B 16.9, MSS-SP-43

- Schedule : 10S/40S/80S/160S/XXS

- Stainless Steel : ASTM A 403 WP-TP 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A815- UNS S31803, S32750, S32760, S32205

ALLOY STEEL, CARBON STEEL & LTCS BARREL NIPPLES:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S/160S/XXS

- Alloy Steel : ASTM A 234 WPB, WP5,WP9,WP11,WP12,WP91

- Carbon Steel : ASTM A 234 WPB, IS 1239 PART II

- Low Temperature Carbon Steel : ASTM A-420 WPL6

- Other Services : Hot Dip Galvanizing, Sand Blasting

COPPER & NICKEL ALLOYS BARREL NIPPLES:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400

- Inconel : UNS N06600, N06601, N006625, N08800, N08810, N08825

- Hastelloy : UNS N10276, N06022, N10665, N06455

- SMO 254: UNS S31254