Before we proceed to the topic of how to choose the right Precision Slit Coils for your projects, let us discuss what makes these materials unique and how to make the right choice. Regardless of whether you are an engineer, a manufacturer or you are in charge of a production line, the right choice can go a long way in determining the quality of the final product. Below is a guide that can assist you in making a right decision

What Are Precision Slit Coils?

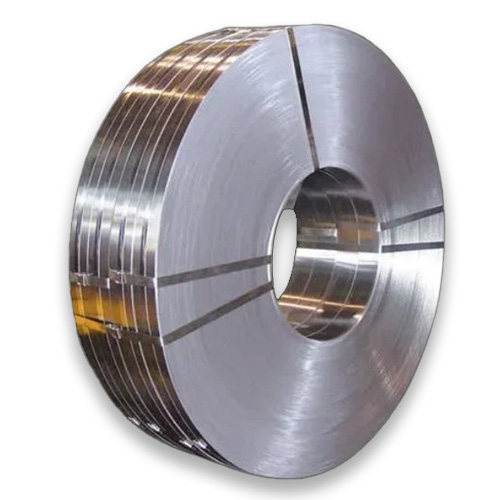

Precision Slit Coils are long and thin and are derived from larger steel coils or coils made from other metals. These coils are produced to fit specific dimensions in width and thickness and surface finish to make them ideal for uses where accuracy is paramount. They are commonly applied in automotive, aerospace and construction industries because they are reliable and flexible

Key Factors to Consider

- Material Specifications :

The first thing that a buyer should know when deciding on which Precision Slit Coils to purchase is the material. Precision Slit Coils are available in various types of metals including stainless steel, carbon steel as well as aluminium. Different types of metals are available and each of them has its own characteristics like corrosion resistance, strength and weight. For example, if you require your coils to have better rust protection, then stainless steel is the way to go. - Width and Thickness :

The name says it all and it is important to make sure that the coils that you order are of the right width and thickness. The size of the coils should be compatible with the manufacturing requirements so that no problems are encountered in the process. Most of the Precision Slit Coils manufacturers have standard and/or special sizes, thus you can get coils of the right size to fit your machinery and project. - Surface Finish :

The type of surface finish given to the coils is another important consideration. Depending on your application, you may require a shiny or a glossy surface or a rather coarse surface. The finish can affect the look and performance of the end product and therefore it is important to select coils that will offer the desired finish. - Quality and Consistency :

When choosing Precision Slit Coils, quality and consistency must be considered. Coils that have uneven dimensions or surface finish can cause problems in the finished product. One should always select the supplier of Precision Slit Coils from a company that is well established and provides good quality material. It is recommended to work with suppliers who have the necessary certificates and who have a good reputation. - Cost vs. Value :

It is always important to consider the cost, but it should not be the only factor that you have to consider. It is always advisable to go for the higher priced coils since they are likely to be of better quality and may perform better hence reducing on the cost of defects and time lost. Consider the total value of the product, including aspects such as the product’s sturdiness and efficiency, to avoid making an expensive decision.

Finding the Right Supplier

Selecting the right Precision Slit Coils stockist can be a big boon to your business in terms of sourcing. Seek for suppliers who provide a broad range of materials and sizes and those that can develop unique solutions. Other ways of getting a good supplier include; reading reviews and asking for recommendations. Ideally, the stockist should be one who has the knowledge of your industry and be willing to help you with your choice of stocks

Working with a Manufacturer

When involved with Precision Slit Coils manufacturers, it is very important to be able to communicate extensively. Be very specific on your needs and communicate them to the manufacturer so that he or she can meet them. It also helps to build a good rapport with your manufacturer in case of any problems they can be solved easily

Conclusion

Choosing the right Precision Slit Coils involves careful consideration of various factors, including material specifications, dimensions, surface finish, and overall quality. By understanding your specific needs and working with reputable suppliers and manufacturers, you can ensure that you select coils that will enhance the performance and reliability of your projects

Remember to evaluate both cost and value to make a decision that supports your long-term goals. With the right Precision Slit Coils, you’ll be well-equipped to achieve high-quality results and maintain a competitive edge in your industry

You can Contact Alloyed Sustainables today at sales@alloyedsustainable.com to learn more about our Slit Coils and how they can be uses in various industries.