Buttweld Fittings play a crucial role in various industries, facilitating a seamless flow of fluids through welded connections. These fittings come in different types such as Elbows and Reducers, made from materials like Stainless Steel, Alloy Steel, Copper & Nickel Alloys, and more. Alloyed Sustainables LLP stands as a Reputable Manufacturer of High-Quality Buttweld Fittings in Mumbai, India. Our products serve industries including Oil and Gas, Chemical Processing, and Water Treatment.

What Is Buttweld Pipe Fittings?

Buttweld Pipe Fittings are vital components in piping systems. They serve the purpose of connecting and redirecting the flow of fluids through weldable pipe fittings. The fittings feature a beveled end that forms a secure and watertight joint when welded pipe fittings together. This welding process guarantees seamless fluid movement within the system, making Buttweld Fittings a preferred choice across various industries.

Where are Buttweld Pipe Fittings Used?

Buttweld Fittings are widely utilized across various industries, including Oil and Gas, Chemical, Petrochemical, Water Treatment, and more. They play a significant role in ensuring seamless operations within these sectors.

1. The Oil and Gas Industry heavily relies on the utilization of Buttweld Fittings to ensure efficient fluid transportation and effective flow management within pipelines.

2. The Chemical and Petrochemical Industry relies on fittings that securely connect pipes. These fittings play a crucial role in transporting chemicals and petrochemical products throughout the industry.

3. Water Treatment and distribution involve using fittings to guarantee the continual flow of safe and reliable potable water.

4. The Power Generation Industry relies on the use of Buttweld Pipe Fittings to efficiently transport vital fluids for its processes.

How are Buttweld Pipe Fittings Made?

Buttweld Pipe Fittings are manufactured using a process called hot forming. Below is a simplified outline of the production procedure:

1. Material Selection: In this initial stage of the process, the selection of suitable raw materials becomes crucial for Buttweld Fittings. The chosen materials must possess specific mechanical and chemical properties to ensure optimal performance and functionality in the final product.

2. Cutting and Shaping: Advanced machinery and cutting-edge techniques are used to precisely cut the chosen raw materials into the required sizes and shapes for each type of Buttweld Fitting. This step plays a crucial role in achieving accurate dimensions and consistent uniformity within the fitting.

3. Heating and Forming: Once the raw materials have been cut and shaped, they go through a heating process to make them. This enables specialised machinery and forming techniques to shape the materials into the desired form.

4. Cooling: Once the materials are shaped into the desired form, they undergo a rapid cooling process. This essential step not only maintains the new shape but also enhances their structural integrity. By ensuring proper cooling, it guarantees that the material retains its intended dimensions and properties, ultimately setting the shape for the Buttweld Fitting.

5. Finishing: In the final stage, the Buttweld Pipe Fittings are subjected to finishing processes to refine the surface, improve its appearance, and meet required specifications. Finishing may involve processes such as grinding, polishing, coating, or other surface treatments to enhance durability, corrosion resistance, and overall aesthetics of the Buttweld Fittings. This step ensures the fittings are ready for assembly and use.

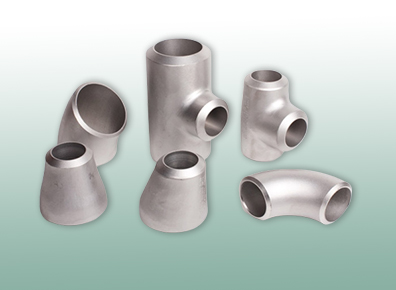

What are the Different Types of Buttweld Pipe Fittings

1. 45°, 90°, and 180° Elbows: Elbows are used to change the direction of the pipe in a system. They come in various angles like 45°, 90°, and 180°, catering to specific requirements.

2. Equal, Unequal and Cross Tees: Tees are fittings that allow the flow of fluid to be divided into two directions, creating a T-shaped junction.

3. Reducers: Reducers are employed to transition from one pipe size to another, ensuring a smooth flow in the piping system.

4. End Caps: Caps are used to close the end of a pipe, providing protection and preventing any substance from escaping.

What Materials are Used to Manufacture Buttweld Pipe Fittings by Alloyed Sustainables LLP

At Alloyed Sustainables LLP, a leading Buttweld Pipe Fittings manufacturer in Mumbai, India, we prioritize quality and durability. Our fittings are crafted from a variety of materials to cater to diverse industrial needs.

1. Stainless Steel & Duplex Steel: Stainless Steel and Duplex Steel Buttweld Pipe Fittings offer exceptional corrosion resistance, making them suitable for aggressive environments and applications.

2. Alloy Steel, Carbon Steel & LTCS: Alloy steel, Low-Temperature Carbon Steel and Carbon Steel Buttweld Pipe Fittings are known for their strength and ability to withstand high pressure and temperature.

3. Copper & Nickel Alloys: Copper and Nickel Alloys Buttweld Pipe Fittings are chosen for their excellent conductivity and resistance to corrosion in various conditions.

4. Nickel, Monel, Inconel, Hastelloy, SMO 254: Fittings made from Nickel, Monel, Inconel, Hastelloy provide superior resistance to oxidation, erosion, and corrosion, making them ideal for critical applications in harsh environments.

Features of Buttweld Pipe Fittings

1. Strong and Durable: Buttweld Fittings provide a robust and long-lasting joint.

2. Leak-Proof Connection: Welded joints ensure a leak-free connection.

3. Versatility: Available in various materials, sizes, and types for diverse applications.

4. Smooth Flow: The seamless design allows for smooth fluid or gas flow.

Choose Alloyed Sustainables LLP for Reliable Buttweld Pipe Fittings

Alloyed Sustainables LLP is a Leading Buttweld Fittings Manufacturer in Mumbai, India, known for prioritizing quality and durability. Our diverse range of materials ensures suitability for even the most demanding applications. We offer Carbon Steel Buttweld Fittings, Inconel Buttweld Fittings, Hastelloy Buttweld Pipe Fittings, Alloy Steel Buttweld Pipe Fittings, Duplex Buttweld Fittings, and proudly cater to the needs of our customers in the Oil and Gas, Chemical Processing, Water Treatment Facilities, etc.

To learn more about Buttweld Pipe Fittings and explore the extensive product offerings from Alloyed Sustainable LLP, reach out to us today. We can provide you with detailed information to make an informed decision for your piping system’s efficiency and reliability. For inquiries or further product knowledge, please feel free to contact us through any of the following means:

Email: sales@alloyedsustainable.com

Phone Number: +91-9920-787-848

Feel free to reach out via email or phone for any questions or specific requirements you may have. Our team will be happy to assist you with your industrial needs.