Grades

categories

Categories

enquire now

LATERALS

Alloyed Sustainables LLP is a prominent manufacturer and exporter of high-quality Lateral. Our core values are centered on quality control, customer satisfaction, and product excellence. With meticulous attention to manufacturing processes, the company offers Laterals that meets diverse customer requirements in terms of dimensions, sizes, standards, types, and classes. Through our offerings, we not only meet industry standards but also set new benchmarks, reinforcing our reputation among both existing and prospective customers

Description:

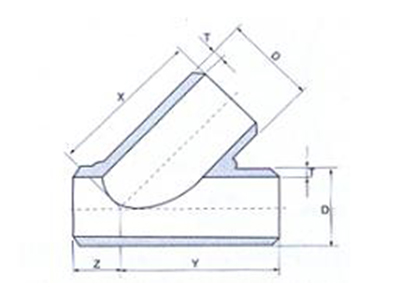

Laterals refer to a type of butt weld pipe fitting used in piping systems. A lateral is designed to branch off a main pipeline at a 45-degree angle, allowing the flow of fluids or gases to be redirected in a different direction, this branching-off design is particularly useful when creating complex piping systems that require multiple connections. We employ a lot of qualified specialists; they always abide by the established national and international norms and requirements. Laterals are manufactured and available in a variety of specifications, materials, sizes and grades.

Key Features of Laterals:

- Precision Engineering: Our laterals are meticulously crafted to exact dimensions and specifications, ensuring a seamless fit within complex piping systems.

- Efficient Fluid Management: Designed with a gradual 45-degree branching angle, our laterals reduce turbulence and optimize fluid and gas flow efficiency in various industrial applications.

- Variety of Configurations: Offering both concentric and eccentric options, clients can choose the ideal lateral configuration to suit their specific operational needs.

- Durability and Longevity: Constructed using premium materials and advanced techniques, our laterals exhibit robustness and longevity, even in demanding conditions.

- Minimized Pressure Drop: Precise engineering minimizes pressure drop, ensuring a consistent and efficient flow of fluids or gases throughout the piping system.

Application across Industries:

- Oil and Gas: Our laterals play a vital role in oil and gas piping systems, directing flows efficiently in extraction, processing, and distribution processes.

- Chemical Processing: In chemical plants, our laterals help manage diverse fluid streams, ensuring precise mixing and separation for optimal production.

- Power Generation: Within power plants, our laterals aid in the efficient transport of fluids for cooling, heating, and energy conversion processes.

- Water Treatment: Laterals contribute to water treatment facilities, guiding flows for filtration, purification, and distribution.

Our catalog includes laterals made from a variety of materials and grades to meet the needs of our clients in many industries.

STAINLESS STEEL & DUPLEX STEEL LATERALS:

Specifications:

- Size : 1/2″ to 36NB”, ANSI/ASME B 16.9, MSS-SP-43

- Schedule : 10S/40S/80S/160S/XXS

- Stainless Steel : ASTM A 403 WP-TP 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A815- UNS S31803, S32750, S32760, S32205

ALLOY STEEL, CARBON STEEL & LTCS LATERALS:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S/160S/XXS

- Alloy Steel : ASTM A 234 WPB, WP5,WP9,WP11,WP12,WP91

- Carbon Steel : ASTM A 234 WPB, IS 1239 PART II

- Low Temperature Carbon Steel : ASTM A-420 WPL6

- Other Services : Hot Dip Galvanizing, Sand Blasting

COPPER & NICKEL ALLOYS LATERALS:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400

- Inconel : UNS N06600, N06601, N006625, N08800, N08810, N08825

- Hastelloy : UNS N10276, N06022, N10665, N06455

- SMO : 254 UNS S31254

LATERALS

Alloyed Sustainables LLP is a prominent manufacturer and exporter of high-quality Lateral. Our core values are centered on quality control, customer satisfaction, and product excellence. With meticulous attention to manufacturing processes, the company offers Laterals that meets diverse customer requirements in terms of dimensions, sizes, standards, types, and classes. Through our offerings, we not only meet industry standards but also set new benchmarks, reinforcing our reputation among both existing and prospective customers

Description:

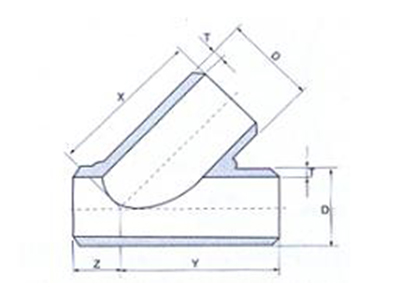

Laterals refer to a type of butt weld pipe fitting used in piping systems. A lateral is designed to branch off a main pipeline at a 45-degree angle, allowing the flow of fluids or gases to be redirected in a different direction, this branching-off design is particularly useful when creating complex piping systems that require multiple connections. We employ a lot of qualified specialists; they always abide by the established national and international norms and requirements. Laterals are manufactured and available in a variety of specifications, materials, sizes and grades.

Key Features of Laterals:

- Precision Engineering: Our laterals are meticulously crafted to exact dimensions and specifications, ensuring a seamless fit within complex piping systems.

- Efficient Fluid Management: Designed with a gradual 45-degree branching angle, our laterals reduce turbulence and optimize fluid and gas flow efficiency in various industrial applications.

- Variety of Configurations: Offering both concentric and eccentric options, clients can choose the ideal lateral configuration to suit their specific operational needs.

- Durability and Longevity: Constructed using premium materials and advanced techniques, our laterals exhibit robustness and longevity, even in demanding conditions.

- Minimized Pressure Drop: Precise engineering minimizes pressure drop, ensuring a consistent and efficient flow of fluids or gases throughout the piping system.

Application across Industries:

- Oil and Gas: Our laterals play a vital role in oil and gas piping systems, directing flows efficiently in extraction, processing, and distribution processes.

- Chemical Processing: In chemical plants, our laterals help manage diverse fluid streams, ensuring precise mixing and separation for optimal production.

- Power Generation: Within power plants, our laterals aid in the efficient transport of fluids for cooling, heating, and energy conversion processes.

- Water Treatment: Laterals contribute to water treatment facilities, guiding flows for filtration, purification, and distribution.

Our catalog includes laterals made from a variety of materials and grades to meet the needs of our clients in many industries.

STAINLESS STEEL & DUPLEX STEEL LATERALS:

Specifications:

- Size : 1/2″ to 36NB”, ANSI/ASME B 16.9, MSS-SP-43

- Schedule : 10S/40S/80S/160S/XXS

- Stainless Steel : ASTM A 403 WP-TP 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A815- UNS S31803, S32750, S32760, S32205

ALLOY STEEL, CARBON STEEL & LTCS LATERALS:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S/160S/XXS

- Alloy Steel : ASTM A 234 WPB, WP5,WP9,WP11,WP12,WP91

- Carbon Steel : ASTM A 234 WPB, IS 1239 PART II

- Low Temperature Carbon Steel : ASTM A-420 WPL6

- Other Services : Hot Dip Galvanizing, Sand Blasting

COPPER & NICKEL ALLOYS LATERALS:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400

- Inconel : UNS N06600, N06601, N006625, N08800, N08810, N08825

- Hastelloy : UNS N10276, N06022, N10665, N06455

- SMO : 254 UNS S31254