Grades

categories

Categories

enquire now

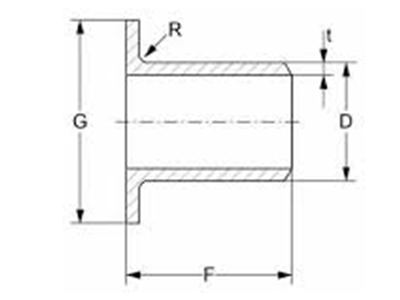

LONG STUBEND

Alloyed Sustainables is a manufacturer and exporter of high-quality long stub ends. With a strong dedication to sustainability and excellence, we take pride in offering a comprehensive range of superior Long Stubends in various Specifications, Sizes, and Grades. These Stubends are crafted from premium grade materials that have exceptional chemical and mechanical qualities to meet the diverse needs of industries worldwide.

Description:

A long stub end is a type of pipe fitting used in piping systems. It is typically used with lap joint flanges, which are also known as “stub flanges.” A stub end and a lap joint flange together form a joint that allows easy disassembly and alignment of piping components. Long stub ends are particularly useful in situations where frequent disassembly or alignment adjustments are necessary, such as in piping systems where equipment needs to be periodically removed or replaced. By using a long stub end and lap joint flange combination, you can avoid the need to cut and re-weld the pipe every time maintenance or changes are required, saving time and resources.

Key Features of Stubends:

- Extended Length: Long stub ends are distinguished by their elongated size, providing increased surface area for welding and more bolt options on the lap joint flange for robust connections.

- Alignment Advantage: Offering adjustable alignment like standard stub ends, long versions are particularly beneficial for applications requiring thicker insulation or when precise alignment is crucial.

- Rotational Flexibility: Just as with regular stub ends, long stub ends grant rotational freedom due to lap joint flanges, ensuring easy alignment without having to manipulate the entire pipe.

- Strong Connection: Long stub ends are welded to larger pipes, delivering a sturdy connection; their extended length also permits more bolts for lap joint flanges, further reinforcing the joint.

- Thermal Expansion Accommodation: The added length of long stub ends accommodates thermal expansion better, reducing stress and strain on the piping system.

Application across Industries:

- Chemical Processing: Similar to petrochemical plants, chemical processing facilities often require quick and efficient maintenance. Long stub ends provide a solution that minimizes downtime during maintenance activities.

- Water Treatment: Water treatment plants often need to adjust their systems for optimal performance. Long stub ends make it easier to modify or replace components without major disruptions.

- Power Generation: Power plants, whether nuclear, thermal, or renewable, rely on complex piping systems. Long stub ends are useful when maintaining or upgrading these systems.

- Shipbuilding and Maritime: Ships and offshore platforms have intricate piping networks. Long stub ends simplify repairs and replacements, which can be crucial in remote locations.

We offer Long Stubends expertly manufactured from a variety of materials and grades, intricately designed to meet the unique needs of our clients spanning a broad spectrum of industries.

STAINLESS STEEL & DUPLEX STEEL LONG STUBENDS:

Specifications:

- Size : 1/2″ to 36NB”, ANSI/ASME B 16.9, MSS-SP-43

- Schedule : 10S/40S/80S/160S/XXS

- Stainless Steel : ASTM A 403 WP-TP 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A815- UNS S31803, S32750, S32760, S32205

ALLOY STEEL, CARBON STEEL & LTCS LONG STUBENDS:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S/160S/XXS

- Alloy Steel : ASTM A 234 WPB, WP5,WP9,WP11,WP12,WP91

- Carbon Steel : ASTM A 234 WPB, IS 1239 PART II

- Low Temperature Carbon Steel : ASTM A-420 WPL6

- Other Services : Hot Dip Galvanizing, Sand Blasting

COPPER & NICKEL ALLOYS LONG STUBENDS:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400

- Inconel : UNS N06600, N06601, N006625, N08800, N08810, N08825

- Hastelloy : UNS N10276, N06022, N10665, N06455

- SMO 254 : UNS S31254

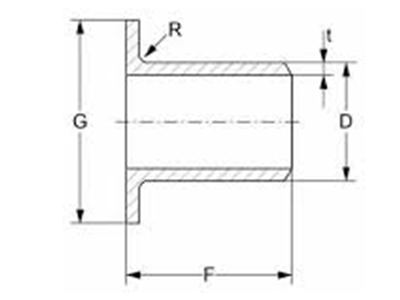

LONG STUBEND

Alloyed Sustainables is a manufacturer and exporter of high-quality long stub ends. With a strong dedication to sustainability and excellence, we take pride in offering a comprehensive range of superior Long Stubends in various Specifications, Sizes, and Grades. These Stubends are crafted from premium grade materials that have exceptional chemical and mechanical qualities to meet the diverse needs of industries worldwide.

Description:

A long stub end is a type of pipe fitting used in piping systems. It is typically used with lap joint flanges, which are also known as “stub flanges.” A stub end and a lap joint flange together form a joint that allows easy disassembly and alignment of piping components. Long stub ends are particularly useful in situations where frequent disassembly or alignment adjustments are necessary, such as in piping systems where equipment needs to be periodically removed or replaced. By using a long stub end and lap joint flange combination, you can avoid the need to cut and re-weld the pipe every time maintenance or changes are required, saving time and resources.

Key Features of Stubends:

- Extended Length: Long stub ends are distinguished by their elongated size, providing increased surface area for welding and more bolt options on the lap joint flange for robust connections.

- Alignment Advantage: Offering adjustable alignment like standard stub ends, long versions are particularly beneficial for applications requiring thicker insulation or when precise alignment is crucial.

- Rotational Flexibility: Just as with regular stub ends, long stub ends grant rotational freedom due to lap joint flanges, ensuring easy alignment without having to manipulate the entire pipe.

- Strong Connection: Long stub ends are welded to larger pipes, delivering a sturdy connection; their extended length also permits more bolts for lap joint flanges, further reinforcing the joint.

- Thermal Expansion Accommodation: The added length of long stub ends accommodates thermal expansion better, reducing stress and strain on the piping system.

Application across Industries:

- Chemical Processing: Similar to petrochemical plants, chemical processing facilities often require quick and efficient maintenance. Long stub ends provide a solution that minimizes downtime during maintenance activities.

- Water Treatment: Water treatment plants often need to adjust their systems for optimal performance. Long stub ends make it easier to modify or replace components without major disruptions.

- Power Generation: Power plants, whether nuclear, thermal, or renewable, rely on complex piping systems. Long stub ends are useful when maintaining or upgrading these systems.

- Shipbuilding and Maritime: Ships and offshore platforms have intricate piping networks. Long stub ends simplify repairs and replacements, which can be crucial in remote locations.

We offer Long Stubends expertly manufactured from a variety of materials and grades, intricately designed to meet the unique needs of our clients spanning a broad spectrum of industries.

COPPER & NICKEL ALLOYS LONG STUBENDS:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400

- Inconel : UNS N06600, N06601, N006625, N08800, N08810, N08825

- Hastelloy : UNS N10276, N06022, N10665, N06455

- SMO 254 : UNS S31254

ALLOY STEEL, CARBON STEEL & LTCS LONG STUBENDS:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S/160S/XXS

- Alloy Steel : ASTM A 234 WPB, WP5,WP9,WP11,WP12,WP91

- Carbon Steel : ASTM A 234 WPB, IS 1239 PART II

- Low Temperature Carbon Steel : ASTM A-420 WPL6

- Other Services : Hot Dip Galvanizing, Sand Blasting

COPPER & NICKEL ALLOYS LONG STUBENDS:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400

- Inconel : UNS N06600, N06601, N006625, N08800, N08810, N08825

- Hastelloy : UNS N10276, N06022, N10665, N06455

- SMO 254 : UNS S31254