Grades

categories

Categories

enquire now

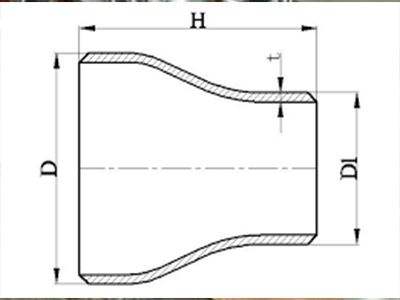

REDUCER

As a trusted manufacturer of Reducer Fittings, Alloyed Sustainables is dedicated to providing high-quality items that align with the varied demands of industries. With an enduring focus on achieving superiority, Alloyed Sustainables remains a reputable entity in the field of Reducer Fittings production. Our resolute dedication to accuracy, longevity, and effectiveness distinguishes us within the industry.

Description:

Reducers can be divided into two main categories: the eccentric and the concentric. The eccentric reducer is used to connect pipes of different sizes in plumbing systems. It has a curved edge that runs parallel to the pipe it’s attached to. The concentric reducer is used when pipes run in parallel. It’s a cone-shaped device that’s used when there’s a big difference in pipe diameters. Our Butt-Weld reducer fittings come in a variety of materials, like Carbon Steel, Alloy Steels, Stainless Steel, Hastelloy, Inconel, Monel, Duplex Steel, Super Duplex, SMO 254, And Nickel.

Key features of Reducer:

- Bore Transition: Reducer fittings serve to smoothly transition pipe diameters, facilitating optimal flow while minimizing disruptions in pipelines for efficient fluid or gas conveyance.

- Connection: Reducers are typically attached using butt-welding, creating strong, leak-resistant joints ideal for high-pressure and high-temperature environments.

- Flow Optimization: Well-designed reducers minimize turbulence and pressure drops, optimizing flow dynamics as fluids or gases move between pipes of varying diameters, promoting energy efficiency.

- Versatility: Reducers’ adaptability to diverse pipeline systems and their capability to address various operational needs underscore their versatility across industrial processes.

- Seamless Integration: Correctly installed reducer fittings blend seamlessly into pipeline systems, promoting continuous, efficient flow without leaks or disruptions.

Application across Industries:

- Shipbuilding: Reducers are utilized in shipbuilding to manage fluid movement within different onboard systems, enhancing the functionality and performance of marine vessels.

- Water Treatment: Reducers contribute to effective water treatment processes by controlling fluid movement in treatment facilities, ensuring optimal chemical dosing and filtration efficiency.

- Chemical and Petrochemical: In chemical and petrochemical sectors, reducers enable the seamless movement of diverse chemicals through pipelines of varying sizes, ensuring precise mixing and safe processing.

- Power Generation: Within power plants, reducers regulate fluid flow in steam, water, and cooling systems, enhancing energy production and distribution while upholding operational reliability.

We manufacture reducers from a wide range of materials and grades, intricately designed to cater to the unique requirements of our clients spanning various industries.

Types

- Concentric Reducer

- Eccentric Reducer

STAINLESS STEEL & DUPLEX STEEL REDUCER:

Specifications:

- Size : 1/2″ to 36NB”, ANSI/ASME B 16.9, MSS-SP-43

- Schedule : 10S/40S/80S/160S/XXS

- Stainless Steel : ASTM A 403 WP-TP 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A815- UNS S31803, S32750, S32760, S32205

ALLOY STEEL, CARBON STEEL & LTCS REDUCER:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S/160S/XXS

- Alloy Steel : ASTM A 234 WPB, WP5,WP9,WP11,WP12,WP91

- Carbon Steel : ASTM A 234 WPB, IS 1239 PART II

- Low Temperature Carbon Steel : ASTM A-420 WPL6

- Other Services : Hot Dip Galvanizing, Sand Blasting

COPPER & NICKEL ALLOYS REDUCER:

Specifications:

- Size : 1/2″ to 36NB” ,ANSI/ASME B 16.9

- Schedule : 10S/40S/80S

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400

- Inconel : UNS N06600, N06601, N006625, N08800, N08810, N08825

- Hastelloy : UNS N10276, N06022, N10665, N06455

- SMO : 25 UNS S31254

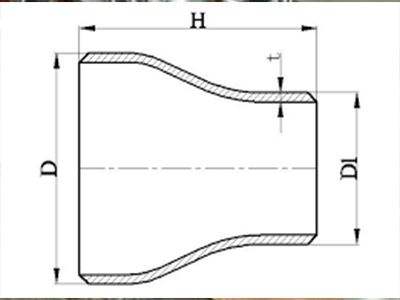

REDUCER

As a trusted manufacturer of Reducer Fittings, Alloyed Sustainables is dedicated to providing high-quality items that align with the varied demands of industries. With an enduring focus on achieving superiority, Alloyed Sustainables remains a reputable entity in the field of Reducer Fittings production. Our resolute dedication to accuracy, longevity, and effectiveness distinguishes us within the industry.

Description:

Reducers can be divided into two main categories: the eccentric and the concentric. The eccentric reducer is used to connect pipes of different sizes in plumbing systems. It has a curved edge that runs parallel to the pipe it’s attached to. The concentric reducer is used when pipes run in parallel. It’s a cone-shaped device that’s used when there’s a big difference in pipe diameters. Our Butt-Weld reducer fittings come in a variety of materials, like Carbon Steel, Alloy Steels, Stainless Steel, Hastelloy, Inconel, Monel, Duplex Steel, Super Duplex, SMO 254, And Nickel.

Key features of Reducer:

- Bore Transition: Reducer fittings serve to smoothly transition pipe diameters, facilitating optimal flow while minimizing disruptions in pipelines for efficient fluid or gas conveyance.

- Connection: Reducers are typically attached using butt-welding, creating strong, leak-resistant joints ideal for high-pressure and high-temperature environments.

- Flow Optimization: Well-designed reducers minimize turbulence and pressure drops, optimizing flow dynamics as fluids or gases move between pipes of varying diameters, promoting energy efficiency.

- Versatility: Reducers’ adaptability to diverse pipeline systems and their capability to address various operational needs underscore their versatility across industrial processes.

- Seamless Integration: Correctly installed reducer fittings blend seamlessly into pipeline systems, promoting continuous, efficient flow without leaks or disruptions.

Application across Industries:

- Shipbuilding: Reducers are utilized in shipbuilding to manage fluid movement within different onboard systems, enhancing the functionality and performance of marine vessels.

- Water Treatment: Reducers contribute to effective water treatment processes by controlling fluid movement in treatment facilities, ensuring optimal chemical dosing and filtration efficiency.

- Chemical and Petrochemical: In chemical and petrochemical sectors, reducers enable the seamless movement of diverse chemicals through pipelines of varying sizes, ensuring precise mixing and safe processing.

- Power Generation: Within power plants, reducers regulate fluid flow in steam, water, and cooling systems, enhancing energy production and distribution while upholding operational reliability.

We manufacture reducers from a wide range of materials and grades, intricately designed to cater to the unique requirements of our clients spanning various industries.

Types

- Concentric Reducer

- Eccentric Reducer

STAINLESS STEEL & DUPLEX STEEL REDUCER:

Specifications:

- Size : 1/2″ to 36NB”, ANSI/ASME B 16.9, MSS-SP-43

- Schedule : 10S/40S/80S/160S/XXS

- Stainless Steel : ASTM A 403 WP-TP 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A815- UNS S31803, S32750, S32760, S32205

ALLOY STEEL, CARBON STEEL & LTCS REDUCER:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S/160S/XXS

- Alloy Steel : ASTM A 234 WPB, WP5,WP9,WP11,WP12,WP91

- Carbon Steel : ASTM A 234 WPB, IS 1239 PART II

- Low Temperature Carbon Steel : ASTM A-420 WPL6

- Other Services : Hot Dip Galvanizing, Sand Blasting

COPPER & NICKEL ALLOYS REDUCER:

Specifications:

- Size : 1/2″ to 36NB” ,ANSI/ASME B 16.9

- Schedule : 10S/40S/80S

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400

- Inconel : UNS N06600, N06601, N006625, N08800, N08810, N08825

- Hastelloy : UNS N10276, N06022, N10665, N06455

- SMO : 25 UNS S31254