Grades

categories

Categories

enquire now

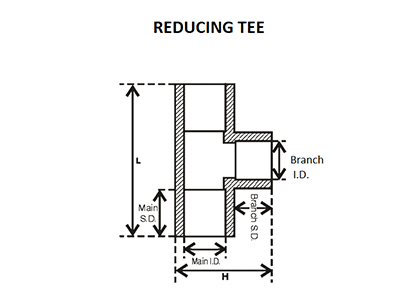

REDUCING TEE

Alloyed Sustainables is an industry leader, specialized in the production of high-quality reducer tees. Our reducer tees are professionally manufactured from high-quality materials, assuring superior performance and durability. A strong dedication to client service is at the heart of our operations, reflecting the basic principles that propel us forward. We believe in building close connections with our clients in order to meet and surpass their expectations.

Description:

A reducing tee is a type of butt weld fitting used in piping systems to connect pipes of different diameters. It has three openings, with one inlet and two outlets arranged in a “T” shape. The main purpose of a reducing tee is to allow the flow of fluid or gas to be diverted into two different pipes of varying sizes. Reducing tee butt weld fittings are commonly used in various industries, including oil and gas, chemical processing, water treatment, and more, wherever pipes of different sizes need to be joined together while maintaining a smooth flow of fluids or gases.

Key Features of Reducer Tee:

- T-Shaped Design: A reducer tee has a “T” shape with one inlet and two outlets, allowing the main line to connect to two smaller branch lines at a 90-degree angle.

- Size Transition: It facilitates the transition of fluid or gas flow between pipes of different diameters, reducing turbulence and pressure drop for efficient conveyance.

- Butt Welding: This fitting is commonly connected through butt welding, where the ends of the pipes and the tee are melted and fused to create a secure joint.

- Pressure Ratings: The fittings have defined pressure ratings based on factors like material, temperature, and pipe size, ensuring safe operation under specific conditions.

- Efficient Flow: Reducer tees play a critical role in directing fluids or gases smoothly between pipes of varying sizes, enhancing overall system performance.

Application across Industries:

- Marine Industry: In shipbuilding, reducer tees play a role in fluid systems, connecting pipes for water, fuel, and other liquids, contributing to the efficient operation of vessels.

- Power Generation: Power plants employ reducer tees to connect steam and cooling water systems, managing flow differentials and aiding efficient energy production and heat dissipation.

- Chemical Processing: Chemical plants utilize reducer tees to ensure precise flow transitions between different pipe sizes, enabling accurate mixing and controlled transport of various chemicals and solutions.

- Water Treatment: Reducer tees are crucial in water treatment facilities, aiding the regulated movement of water between pipes of varying sizes, essential for chemical dosing and water conveyance.

Our offerings include Reducer Tees manufactured using an extensive array of materials and grades, intricately engineered to meet the specific needs of our clients across a diverse range of industries.

STAINLESS STEEL & DUPLEX STEEL REDUCER TEES:

Specifications:

- Size: 1/2″ to 36NB”, ANSI/ASME B 16.9, MSS-SP-43

- Schedule: 10S/40S/80S/160S/XXS

- Stainless Steel : ASTM A 403 WP-TP 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A815- UNS S31803, S32750, S32760, S32205

ALLOY STEEL, CARBON STEEL & LTCS REDUCER TEES:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S/160S/XXS

- Alloy Steel : ASTM A 234 WPB, WP5,WP9,WP11,WP12,WP91

- Carbon Steel : ASTM A 234 WPB, IS 1239 PART II

- Low Temperature Carbon Steel : ASTM A-420 WPL6

- Other Services : Hot Dip Galvanizing, Sand Blasting

COPPER & NICKEL ALLOYS REDUCER TEES:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule :10S/40S/80S

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400

- Inconel : UNS N06600, N06601, N006625, N08800, N08810, N08825

- Hastelloy : UNS N10276, N06022, N10665, N06455

- SMO 254 : UNS S31254

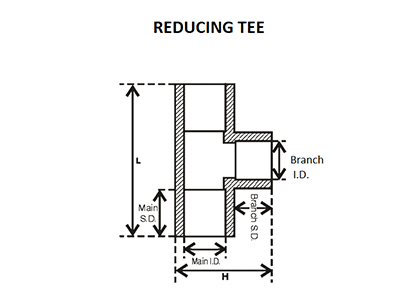

REDUCING TEE

Alloyed Sustainables is an industry leader, specialized in the production of high-quality reducer tees. Our reducer tees are professionally manufactured from high-quality materials, assuring superior performance and durability. A strong dedication to client service is at the heart of our operations, reflecting the basic principles that propel us forward. We believe in building close connections with our clients in order to meet and surpass their expectations.

Description:

A reducing tee is a type of butt weld fitting used in piping systems to connect pipes of different diameters. It has three openings, with one inlet and two outlets arranged in a “T” shape. The main purpose of a reducing tee is to allow the flow of fluid or gas to be diverted into two different pipes of varying sizes. Reducing tee butt weld fittings are commonly used in various industries, including oil and gas, chemical processing, water treatment, and more, wherever pipes of different sizes need to be joined together while maintaining a smooth flow of fluids or gases.

Key Features of Reducer Tee:

- T-Shaped Design: A reducer tee has a “T” shape with one inlet and two outlets, allowing the main line to connect to two smaller branch lines at a 90-degree angle.

- Size Transition: It facilitates the transition of fluid or gas flow between pipes of different diameters, reducing turbulence and pressure drop for efficient conveyance.

- Butt Welding: This fitting is commonly connected through butt welding, where the ends of the pipes and the tee are melted and fused to create a secure joint.

- Pressure Ratings: The fittings have defined pressure ratings based on factors like material, temperature, and pipe size, ensuring safe operation under specific conditions.

- Efficient Flow: Reducer tees play a critical role in directing fluids or gases smoothly between pipes of varying sizes, enhancing overall system performance.

Application across Industries:

- Marine Industry: In shipbuilding, reducer tees play a role in fluid systems, connecting pipes for water, fuel, and other liquids, contributing to the efficient operation of vessels.

- Power Generation: Power plants employ reducer tees to connect steam and cooling water systems, managing flow differentials and aiding efficient energy production and heat dissipation.

- Chemical Processing: Chemical plants utilize reducer tees to ensure precise flow transitions between different pipe sizes, enabling accurate mixing and controlled transport of various chemicals and solutions.

- Water Treatment: Reducer tees are crucial in water treatment facilities, aiding the regulated movement of water between pipes of varying sizes, essential for chemical dosing and water conveyance.

Our offerings include Reducer Tees manufactured using an extensive array of materials and grades, intricately engineered to meet the specific needs of our clients across a diverse range of industries.

STAINLESS STEEL & DUPLEX STEEL REDUCER TEES:

Specifications:

- Size: 1/2″ to 36NB”, ANSI/ASME B 16.9, MSS-SP-43

- Schedule: 10S/40S/80S/160S/XXS

- Stainless Steel : ASTM A 403 WP-TP 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A815- UNS S31803, S32750, S32760, S32205

ALLOY STEEL, CARBON STEEL & LTCS REDUCER TEES:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S/160S/XXS

- Alloy Steel : ASTM A 234 WPB, WP5,WP9,WP11,WP12,WP91

- Carbon Steel : ASTM A 234 WPB, IS 1239 PART II

- Low Temperature Carbon Steel : ASTM A-420 WPL6

- Other Services : Hot Dip Galvanizing, Sand Blasting

COPPER & NICKEL ALLOYS REDUCER TEES:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule :10S/40S/80S

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400

- Inconel : UNS N06600, N06601, N006625, N08800, N08810, N08825

- Hastelloy : UNS N10276, N06022, N10665, N06455

- SMO 254 : UNS S31254