Grades

categories

Categories

enquire now

SHORT STUBEND

Alloyed Sustainables is a trusted manufacturer and Exporter of Short Stubends. These Stubends are manufactured from high-quality raw materials and are available in variety of specifications, sizes, and grades. We strictly adhere to the national and international quality standards. We recognize that customer satisfaction is paramount, and we continuously strive to exceed expectations. These Stubends are useful in applications which demands efficiency and durability.

Description:

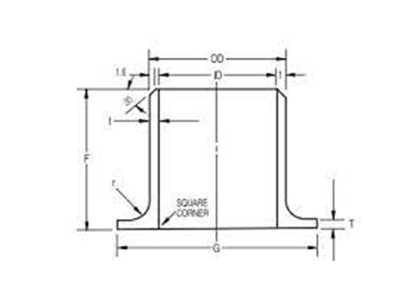

A short stub end is a type of butt weld fitting used in piping systems. It’s a component that’s welded to the pipe in order to create a flanged connection. The short stub end has one end with a plain or slightly bevelled surface that is welded to the pipe, and the other end has a flared or flanged surface that is used to connect to a flange. This allows for easy assembly and disassembly of the piping system.

Key Features of Short Stubends:

- Compact Design: Short stub ends are characterized by their reduced length, making them suitable for installations where space is limited or alignment adjustments are less critical.

- Strong Connection: Despite their shorter size, short stub ends provide a sturdy joint due to welding on the larger pipe and a lap joint flange that can be securely bolted.

- Alignment Efficiency: While offering less adjustability, short stub ends are practical for situations where precise alignment is less crucial or insulation requirements are minimal.

- Space-Saving: Short stub ends are ideal when space optimization is important, allowing for more streamlined installations without compromising joint strength.

- Easy Maintenance: Like longer stub ends, short ones simplify maintenance and repairs by enabling straightforward disassembly and reassembly of the joint, minimizing downtime.

Application across Industries:

- Renewable Energy: In renewable energy projects, such as solar or wind farms, short stub ends connect pipes within compact systems, contributing to efficient energy production.

- Marine and Shipbuilding: In shipbuilding, short stub ends connect pipes within limited spaces, contributing to efficient marine systems’ design.

- Water Treatment: Short stub ends are used in water treatment facilities to connect pipes for water distribution and sewage transport in space-restricted environments.

- Process Industries: In industries like chemical and pharmaceuticals, short stub ends provide a strong and reliable connection for pipes that transport liquids and gases.

We offer Short Stubends skillfully manufactured using a range of materials and grades, intricately tailored to fulfill the distinct requirements of our clients across a wide range of industries.

STAINLESS STEEL & DUPLEX STEEL SHORT STUBENDS:

Specifications:

- Size : 1/2″ to 36NB”, ANSI/ASME B 16.9, MSS-SP-43

- Schedule : 10S/40S/80S/160S/XXS

- Stainless Steel : ASTM A 403 WP-TP 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A815- UNS S31803, S32750, S32760, S32205

ALLOY STEEL, CARBON STEEL & LTCS SHORT STUBENDS:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S/160S/XXS

- Alloy Steel : ASTM A 234 WPB, WP5,WP9,WP11,WP12,WP91

- Carbon Steel : ASTM A 234 WPB, IS 1239 PART II

- Low Temperature Carbon Steel : ASTM A-420 WPL6

- Other Services : Hot Dip Galvanizing, Sand Blasting

COPPER & NICKEL ALLOYS SHORT STUBENDS:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400

- Inconel : UNS N06600, N06601, N006625, N08800, N08810, N08825

- Hastelloy : UNS N10276, N06022, N10665, N06455

- SMO 254: UNS S31254

SHORT STUBEND

Alloyed Sustainables is a trusted manufacturer and Exporter of Short Subends. These Stubends are manufactured from high-quality raw materials and are available in variety of specifications, sizes, and grades. We strictly adhere to the national and international quality standards. We recognize that customer satisfaction is paramount, and we continuously strive to exceed expectations. These Stubends are useful in applications which demands efficiency and durability.

Description:

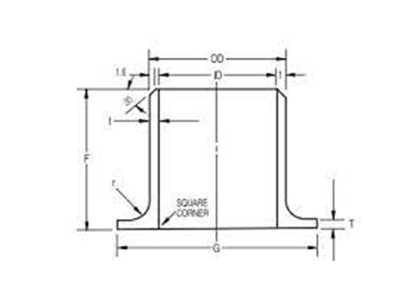

A short stub end is a type of butt weld fitting used in piping systems. It’s a component that’s welded to the pipe in order to create a flanged connection. The short stub end has one end with a plain or slightly bevelled surface that is welded to the pipe, and the other end has a flared or flanged surface that is used to connect to a flange. This allows for easy assembly and disassembly of the piping system.

Key Features of Short Stubends:

- Compact Design: Short stub ends are characterized by their reduced length, making them suitable for installations where space is limited or alignment adjustments are less critical.

- Strong Connection: Despite their shorter size, short stub ends provide a sturdy joint due to welding on the larger pipe and a lap joint flange that can be securely bolted.

- Alignment Efficiency: While offering less adjustability, short stub ends are practical for situations where precise alignment is less crucial or insulation requirements are minimal.

- Space-Saving: Short stub ends are ideal when space optimization is important, allowing for more streamlined installations without compromising joint strength.

- Easy Maintenance: Like longer stub ends, short ones simplify maintenance and repairs by enabling straightforward disassembly and reassembly of the joint, minimizing downtime.

Application across Industries:

- Renewable Energy: In renewable energy projects, such as solar or wind farms, short stub ends connect pipes within compact systems, contributing to efficient energy production.

- Marine and Shipbuilding: In shipbuilding, short stub ends connect pipes within limited spaces, contributing to efficient marine systems’ design.

- Water Treatment: Short stub ends are used in water treatment facilities to connect pipes for water distribution and sewage transport in space-restricted environments.

- Process Industries: In industries like chemical and pharmaceuticals, short stub ends provide a strong and reliable connection for pipes that transport liquids and gases.

We offer Short Stubends skillfully manufactured using a range of materials and grades, intricately tailored to fulfill the distinct requirements of our clients across a wide range of industries.

STAINLESS STEEL & DUPLEX STEEL SHORT STUBENDS:

Specifications:

- Size : 1/2″ to 36NB”, ANSI/ASME B 16.9, MSS-SP-43

- Schedule : 10S/40S/80S/160S/XXS

- Stainless Steel : ASTM A 403 WP-TP 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A815- UNS S31803, S32750, S32760, S32205

ALLOY STEEL, CARBON STEEL & LTCS SHORT STUBENDS:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S/160S/XXS

- Alloy Steel : ASTM A 234 WPB, WP5,WP9,WP11,WP12,WP91

- Carbon Steel : ASTM A 234 WPB, IS 1239 PART II

- Low Temperature Carbon Steel : ASTM A-420 WPL6

- Other Services : Hot Dip Galvanizing, Sand Blasting

COPPER & NICKEL ALLOYS SHORT STUBENDS:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400

- Inconel : UNS N06600, N06601, N006625, N08800, N08810, N08825

- Hastelloy : UNS N10276, N06022, N10665, N06455

- SMO 254: UNS S31254