Grades

categories

Categories

enquire now

SWAGE NIPPLES BUTTWELD FITTINGS

Alloyed Sustainables is dedicated to manufacturing high-quality Swage Nipples that precisely match the distinct needs of our valued clients. Our Swage Nipples are intricately designed to fulfil specific criteria, ensuring their seamless integration within diverse piping systems. Our unwavering commitment lies in employing only the highest quality materials during the manufacturing process, yielding Swage Nipples that distinguish themselves through remarkable durability, extended utility, and precise measurements.

Description:

A swage nipple is a type of pipe fitting used in piping systems to connect two pipes of different diameters. It is a short piece of pipe with one end larger in diameter than the other. Swage nipples are commonly used in various industries, including oil and gas, petrochemical, and manufacturing. Swage nipples are available in different materials such as carbon steel, stainless steel, and other alloys, based on the specific requirements of the piping system.

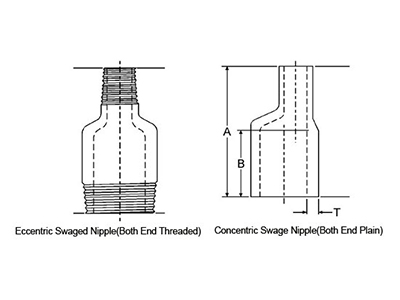

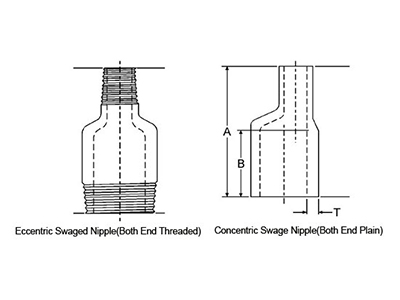

There are two primary types of swage nipples: concentric and eccentric. These types refer to the alignment of the larger and smaller ends of the swage nipple in relation to each other

Concentric Swage Nipple: In a concentric swage nipple, the larger end and the smaller end are aligned in the centre, creating a smooth transition between the two pipe sizes.

Eccentric Swage Nipple: In an eccentric swage nipple, the larger and smaller ends are not aligned in the centre; instead, they are offset.

Key Features of Swage Nipples:

- Exceptional Strength: Our Swage Nipples are crafted using premium materials, ensuring robustness and resilience even in demanding environments.

- Extended Usability: Designed for longevity, our Swage Nipples provide sustained performance over their operational lifespan, minimizing the need for replacements.

- Precise Dimensions: Each Swage Nipple is meticulously manufactured to exact specifications, ensuring seamless integration into piping systems and facilitating secure connections.

- Leak-Proof Joining: Perfect for oil, gas, and petrochemical sectors, our Swage Nipples offer impeccable leak-free connections, ensuring the uninterrupted flow of liquids and gases.

- Optimized Flow: The design of our Swage Nipples is engineered to minimize turbulence and pressure drops, optimizing the flow of fluids and gases.

Application across Industries:

- Oil and Gas Sector: Our Swage Nipples find a crucial role in oil and gas pipelines, ensuring secure connections that withstand high pressures and volatile conditions, enabling the smooth flow of hydrocarbons.

- Chemical Processing: Our Swage Nipples provide dependable connections, maintaining the integrity of fluid transfer systems in chemical processing plants.

- Energy Production: In power plants, including thermal, nuclear, and renewable energy facilities, our Swage Nipples contribute to reliable fluid and gas flow, supporting processes critical to energy production.

- Marine and Offshore: In marine and offshore environments, our Swage Nipples provide dependable connections for pipes in harsh conditions, including saltwater exposure and dynamic movements.

Our selection includes Swage Nipples manufactured using an extensive variety of materials and grades, intricately engineered to address the distinct needs of our clients across diverse industries.

STAINLESS STEEL & DUPLEX STEEL SWAGE NIPPLES:

Specifications:

- Size : 1/2″ to 36NB”, ANSI/ASME B 16.9, MSS-SP-43

- Schedule : 10S/40S/80S/160S/XXS

- Stainless Steel : ASTM A 403 WP-TP 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A815- UNS S31803, S32750, S32760, S32205

ALLOY STEEL, CARBON STEEL & LTCS SWAGE NIPPLES:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S/160S/XXS

- Alloy Steel : ASTM A 234 WPB, WP5,WP9,WP11,WP12,WP91

- Carbon Steel : ASTM A 234 WPB, IS 1239 PART II

- Low Temperature Carbon Steel : ASTM A-420 WPL6

- Other Services : Hot Dip Galvanizing, Sand Blasting

COPPER & NICKEL ALLOYS SWAGE NIPPLES:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400

- Inconel : UNS N06600, N06601, N006625, N08800, N08810, N08825

- Hastelloy : UNS N10276, N06022, N10665, N06455

- SMO 254: UNS S31254

SWAGE NIPPLES BUTTWELD FITTINGS

Alloyed Sustainables is dedicated to manufacturing high-quality Swage Nipples that precisely match the distinct needs of our valued clients. Our Swage Nipples are intricately designed to fulfil specific criteria, ensuring their seamless integration within diverse piping systems. Our unwavering commitment lies in employing only the highest quality materials during the manufacturing process, yielding Swage Nipples that distinguish themselves through remarkable durability, extended utility, and precise measurements.

Description:

A swage nipple is a type of pipe fitting used in piping systems to connect two pipes of different diameters. It is a short piece of pipe with one end larger in diameter than the other. Swage nipples are commonly used in various industries, including oil and gas, petrochemical, and manufacturing. Swage nipples are available in different materials such as carbon steel, stainless steel, and other alloys, based on the specific requirements of the piping system.

There are two primary types of swage nipples: concentric and eccentric. These types refer to the alignment of the larger and smaller ends of the swage nipple in relation to each other

Concentric Swage Nipple: In a concentric swage nipple, the larger end and the smaller end are aligned in the centre, creating a smooth transition between the two pipe sizes.

Eccentric Swage Nipple: In an eccentric swage nipple, the larger and smaller ends are not aligned in the centre; instead, they are offset.

Key Features of Swage Nipples:

- Exceptional Strength: Our Swage Nipples are crafted using premium materials, ensuring robustness and resilience even in demanding environments.

- Extended Usability: Designed for longevity, our Swage Nipples provide sustained performance over their operational lifespan, minimizing the need for replacements.

- Precise Dimensions: Each Swage Nipple is meticulously manufactured to exact specifications, ensuring seamless integration into piping systems and facilitating secure connections.

- Leak-Proof Joining: Perfect for oil, gas, and petrochemical sectors, our Swage Nipples offer impeccable leak-free connections, ensuring the uninterrupted flow of liquids and gases.

- Optimized Flow: The design of our Swage Nipples is engineered to minimize turbulence and pressure drops, optimizing the flow of fluids and gases.

Application across Industries:

- Oil and Gas Sector: Our Swage Nipples find a crucial role in oil and gas pipelines, ensuring secure connections that withstand high pressures and volatile conditions, enabling the smooth flow of hydrocarbons.

- Chemical Processing: Our Swage Nipples provide dependable connections, maintaining the integrity of fluid transfer systems in chemical processing plants.

- Energy Production: In power plants, including thermal, nuclear, and renewable energy facilities, our Swage Nipples contribute to reliable fluid and gas flow, supporting processes critical to energy production.

- Marine and Offshore: In marine and offshore environments, our Swage Nipples provide dependable connections for pipes in harsh conditions, including saltwater exposure and dynamic movements.

Our selection includes Swage Nipples manufactured using an extensive variety of materials and grades, intricately engineered to address the distinct needs of our clients across diverse industries.

STAINLESS STEEL & DUPLEX STEEL SWAGE NIPPLES:

Specifications:

- Size : 1/2″ to 36NB”, ANSI/ASME B 16.9, MSS-SP-43

- Schedule : 10S/40S/80S/160S/XXS

- Stainless Steel : ASTM A 403 WP-TP 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A815- UNS S31803, S32750, S32760, S32205

ALLOY STEEL, CARBON STEEL & LTCS SWAGE NIPPLES:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S/160S/XXS

- Alloy Steel : ASTM A 234 WPB, WP5,WP9,WP11,WP12,WP91

- Carbon Steel : ASTM A 234 WPB, IS 1239 PART II

- Low Temperature Carbon Steel : ASTM A-420 WPL6

- Other Services : Hot Dip Galvanizing, Sand Blasting

COPPER & NICKEL ALLOYS SWAGE NIPPLES:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400

- Inconel : UNS N06600, N06601, N006625, N08800, N08810, N08825

- Hastelloy : UNS N10276, N06022, N10665, N06455

- SMO 254: UNS S31254