Duplex stainless steels are a versatile family of alloys known for their exceptional strength and corrosion resistance. Two popular grades, Duplex S32205 and Duplex S31803, often find themselves in the spotlight due to their similar properties. Let’s delve into their nuances to understand their specific strengths and applications

Understanding Duplex Stainless Steels

Before we dive into the specifics, it’s helpful to understand what makes duplex stainless steels unique. These alloys combine a balanced microstructure of austenite and ferrite, granting them a unique combination of attributes

- High Strength : The balanced microstructure of duplex stainless steels, with roughly equal parts austenite and ferrite, gives them a yield strength that’s typically twice that of standard austenitic stainless steels. This allows for the use of thinner sections, reducing material usage and weight.

- Corrosion Resistance : Duplex stainless steels have a high resistance to various forms of corrosion, including stress corrosion cracking, pitting, and crevice corrosion. This is due to their higher chromium and molybdenum content compared to austenitic stainless steels. This superior corrosion resistance makes them ideal for harsh environments with high chloride concentrations or exposure to acids.

- Cost-Effectiveness : While duplex stainless steels may have a higher upfront cost, their superior strength and corrosion resistance translate to long-term savings. The reduced material usage due to their strength and their longer lifespan due to superior corrosion resistance contribute to lower overall lifecycle costs, making them a cost-effective choice for many applications.

Duplex S31803 (UNS S31803): The Foundation

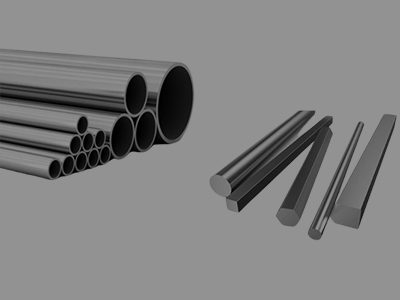

Duplex S31803, also known by its UNS designation UNS S31803, is a foundational grade of duplex stainless steel. It offers a well-balanced combination of strength, corrosion resistance, and weldability. This S31803 material is commonly used in :

- Chemical Processing : The exceptional corrosion resistance of Duplex S31803 makes it a preferred material in the chemical processing industry. It can withstand the corrosive effects of various chemicals, acids, and alkalis, ensuring the longevity and reliability of tanks, piping systems, and heat exchangers used in the production, storage, and transportation of chemicals.

- Oil and Gas : Duplex S31803 is widely used in the oil and gas industry due to its ability to resist the harsh conditions often encountered in this sector. It can handle sour environments containing hydrogen sulfide and carbon dioxide, which are known to cause severe corrosion. Additionally, its resistance to chloride-induced stress corrosion cracking makes it suitable for applications involving seawater injection or production fluids with high chloride content.

- Marine Applications : The marine environment presents a significant challenge to materials due to the constant exposure to saltwater, which can cause rapid corrosion. Duplex S31803’s excellent resistance to saltwater corrosion makes it an ideal choice for various marine applications, including offshore platforms, pipelines, shipbuilding components, and desalination plants. Its high strength-to-weight ratio also contributes to its suitability for these applications.

Duplex S32205 (UNS S32205): Enhanced Performance

Physical Properties

While both Duplex S32205 and S31803 share similar densities around 7.8 g/cm³, there’s a slight distinction in their thermal properties. S32205 edges out S31803 with a thermal conductivity of 15.2 W/m·K compared to 14.5 W/m·K, making it slightly more efficient at transferring heat. In terms of thermal expansion, S31803 exhibits a marginally higher coefficient at 10.8 µm/m·K compared to 10.6 µm/m·K for S32205. This means S31803 expands slightly more when exposed to temperature changes. While these differences are minor, they can be influential in applications where precise thermal management or dimensional stability are critical considerations

Welding and Fabrication

Both S32205 and S31803 exhibit excellent weldability using common welding techniques like TIG, MIG, and submerged arc welding. However, due to its higher alloy content, S32205 may require specific welding procedures to maintain its corrosion resistance properties in the heat-affected zone. Additionally, post-weld heat treatments are often recommended for both grades to relieve residual stresses and optimize their performance

Cost and Availability

Generally, S32205 tends to be slightly more expensive than S31803 due to its higher molybdenum and chromium content. The price difference might be more pronounced for complex components or large quantities. In terms of availability, both grades are readily accessible from reputable suppliers, but S31803 might be more readily available in certain regions or for smaller orders due to its wider usage

Choosing the Right Grade

The choice between Duplex S31803 stainless steel and Duplex S32205 stainless steel often boils down to the specific application requirements. Here’s a quick guideline :

- Standard Environments (S31803) : For applications where moderate corrosion is expected, Duplex S31803 is a well-rounded choice. Its corrosion resistance, while not as extreme as S32205, is still very good and sufficient for many industrial settings. Additionally, its lower cost compared to S32205 makes it an economical option when the most extreme conditions are not present.

- Harsh Conditions (S32205) : When conditions become more demanding, Duplex S32205 steps up. Its enhanced resistance to pitting and crevice corrosion in high-chloride environments makes it the preferred choice for applications like desalination plants or offshore structures. Furthermore, its improved strength and heat resistance make it suitable for higher temperature processes or situations where added mechanical strength is beneficial.

Alloyed Sustainables: Your Partner in Stainless Steel Solutions

At Alloyed Sustainables, we understand that selecting the right material is crucial for your project’s success. Our team of experts is ready to guide you through the complexities of duplex stainless steel selection. Contact us at sales@alloyedsustainable.com to explore how S31803 or S32205 can meet your unique needs