Grades

categories

Categories

enquire now

U-BEND

Alloyed Sustainables LLP is the top U-bend manufacturer and exporter. Our product portfolio has grown steadily over the years as a consequence of our commitment to innovation. Concentrate on meeting and exceeding our esteemed clients’ individual needs. We distribute and export U-bends, return bends, and 180-degree bends in a variety of diameters, requirements, and industry standards.

Description:

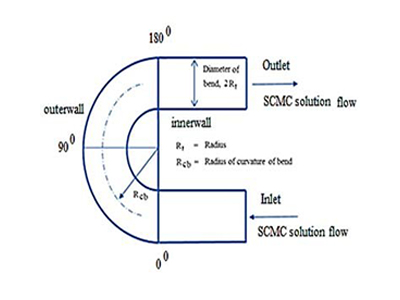

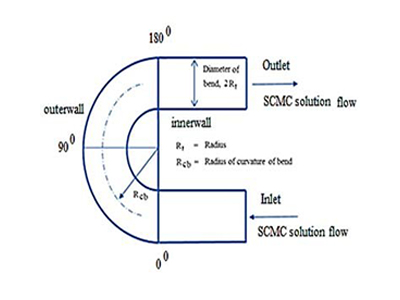

U-bend butt weld fittings are a type of pipe fitting used in piping systems to change the direction of flow in a pipeline. These fittings are designed with a U-shaped bend that allows pipes to be connected at an angle, typically 180 degrees, resembling the letter “U.” Our U-Bend fittings are commonly used in applications where there is a need to redirect the flow of fluid, gases, or other substances, while maintaining a smooth and continuous flow with minimal turbulence.

Key Features of U-Bends:

- Shape and Design: U-bends have a U-shaped configuration that efficiently redirects fluids and gases around obstacles or confined spaces.

- Bending Radius and Angle: Precisely crafted with specific bending radii and angles (often 180 degrees), U-bends fit accurately into systems and enhance heat transfer.

- Heat Transfer Efficiency: U-bends maximize heat exchange efficiency due to increased surface area within a compact tube length.

- Minimized Pressure Drop: The smooth curvature of U-bends maintains fluid flow efficiency, reducing turbulence and pressure drop.

- Corrosion Resistance: U-bends can be crafted from corrosion-resistant materials to extend lifespan and maintain system integrity.

Application across Industries:

- Power Generation: In power plants, U-bend tubes are essential in condenser systems to convert steam back into water for reuse, enhancing thermal efficiency.

- Chemical Processing: U-bends play a role in chemical reactors and heat exchangers, where precise temperature control is crucial for reactions and separations.

- Oil and Gas Industry: U-bends are utilized in offshore platforms and refineries for heating, cooling, and separating fluids in exploration and refining processes.

- Renewable Energy: U-bends play a role in solar thermal systems, facilitating heat exchange in solar collectors for water heating.

Our selection includes U-Bends expertly manufactured from a variety of materials and grades, intricately designed to meet the specific needs of our clients across a diverse range of industries.

STAINLESS STEEL & DUPLEX STEEL U-BENDS:

Specifications:

- Size : 1/2″ to 36NB”, ANSI/ASME B 16.9, MSS-SP-43

- Schedule : 10S/40S/80S/160S/XXS

- Stainless Steel : ASTM A 403 WP – TP

304/ 304H/ 304L/ 316/ 316H/ 316L/ 316Ti/ 309/ 310/ 317L/ 321/ 347/ 904L/ Alloy 20 - Duplex Steel : ASTM A815- UNS S31803, S32750, S32760, S32205

ALLOY STEEL, CARBON STEEL & LTCS U-BENDS:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S/160S/XXS

- Alloy Steel : ASTM A 234 WPB, WP5,WP9,WP11,WP12,WP91

- Carbon Steel : ASTM A 234 WPB, IS 1239 PART II

- Low Temperature Carbon Steel: ASTM A-420 WPL6

- Other Services : Hot Dip Galvanizing, Sand Blasting

COPPER & NICKEL ALLOYS U BEND:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400

- Inconel : UNS N06600, N06601, N006625, N08800, N08810, N08825

- Hastelloy : UNS N10276, N06022, N10665, N06455

- SMO 254 : UNS S31254

U BEND

Alloyed Sustainables LLP is the top U-bend manufacturer and exporter. Our product portfolio has grown steadily over the years as a consequence of our commitment to innovation. Concentrate on meeting and exceeding our esteemed clients’ individual needs. We distribute and export U-bends, return bends, and 180-degree bends in a variety of diameters, requirements, and industry standards.

Description:

U-bend butt weld fittings are a type of pipe fitting used in piping systems to change the direction of flow in a pipeline. These fittings are designed with a U-shaped bend that allows pipes to be connected at an angle, typically 180 degrees, resembling the letter “U.” Our U-Bend fittings are commonly used in applications where there is a need to redirect the flow of fluid, gases, or other substances, while maintaining a smooth and continuous flow with minimal turbulence.

Key Features of U-Bends:

- Shape and Design: U-bends have a U-shaped configuration that efficiently redirects fluids and gases around obstacles or confined spaces.

- Bending Radius and Angle: Precisely crafted with specific bending radii and angles (often 180 degrees), U-bends fit accurately into systems and enhance heat transfer.

- Heat Transfer Efficiency: U-bends maximize heat exchange efficiency due to increased surface area within a compact tube length.

- Minimized Pressure Drop: The smooth curvature of U-bends maintains fluid flow efficiency, reducing turbulence and pressure drop.

- Corrosion Resistance: U-bends can be crafted from corrosion-resistant materials to extend lifespan and maintain system integrity.

Application across Industries:

- Power Generation: In power plants, U-bend tubes are essential in condenser systems to convert steam back into water for reuse, enhancing thermal efficiency.

- Chemical Processing: U-bends play a role in chemical reactors and heat exchangers, where precise temperature control is crucial for reactions and separations.

- Oil and Gas Industry: U-bends are utilized in offshore platforms and refineries for heating, cooling, and separating fluids in exploration and refining processes.

- Renewable Energy: U-bends play a role in solar thermal systems, facilitating heat exchange in solar collectors for water heating.

Our selection includes U-Bends expertly manufactured from a variety of materials and grades, intricately designed to meet the specific needs of our clients across a diverse range of industries.

STAINLESS STEEL & DUPLEX STEEL U-BENDS:

Specifications:

- Size : 1/2″ to 36NB”, ANSI/ASME B 16.9, MSS-SP-43

- Schedule : 10S/40S/80S/160S/XXS

- Stainless Steel : ASTM A 403 WP – TP

304/ 304H/ 304L/ 316/ 316H/ 316L/ 316Ti/ 309/ 310/ 317L/ 321/ 347/ 904L/ Alloy 20 - Duplex Steel : ASTM A815- UNS S31803, S32750, S32760, S32205

ALLOY STEEL, CARBON STEEL & LTCS U-BENDS:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S/160S/XXS

- Alloy Steel : ASTM A 234 WPB, WP5,WP9,WP11,WP12,WP91

- Carbon Steel : ASTM A 234 WPB, IS 1239 PART II

- Low Temperature Carbon Steel: ASTM A-420 WPL6

- Other Services : Hot Dip Galvanizing, Sand Blasting

COPPER & NICKEL ALLOYS U BEND:

Specifications:

- Size : 1/2″ to 36NB” , ANSI/ASME B 16.9

- Schedule : 10S/40S/80S

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400

- Inconel : UNS N06600, N06601, N006625, N08800, N08810, N08825

- Hastelloy : UNS N10276, N06022, N10665, N06455

- SMO 254 : UNS S31254