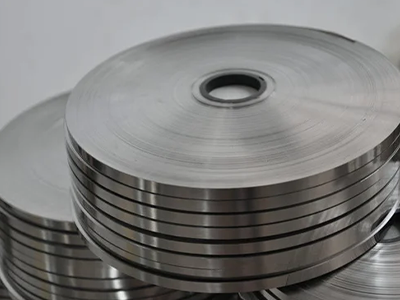

These Monel 400 Bands are widely used in industrial fields because of their excellent corrosion resistance, high strength, and durability. A versatile choice for challenging environments, this high-performance nickel-copper alloy has become a popular selection among engineers and designers in numerous industries. This blog will cover the advantages and industrial uses of Monel 400 Bands, emphasizing how these are indispensable for various industries

Benefits of Monel 400 Bands

Monel 400 Bands Importer Alloyed Sustainables emphasizes several key benefits that make these bands highly sought after in the industrial world

- Corrosion Resistance :

Excellent resistance to corrosion makes Monel 400 a vital material in more aggressive environments. Its ability to withstand the rigors of corrosive environments, including seawater, is unparalleled. Its composition includes nickel (67-70%), copper (29-34%), iron (2%), silicon (0.5%), and carbon (0.25%). This makes it a common choice for marine and chemical processing industries where these properties are needed. It resists the effects of salt and water on naval components, making ship parts durable. Similarly, in the chemical processing industry, Monel 400 is used to resist hydrofluoric and sulfuric acids because of its resistance to these compounds as well as its ability to withstand high temperatures. - High Strength :

Monel 400 is known for its high tensile strength. Despite its ductility, which means it can be shaped into different configurations without losing its durability, it offers significant structural support. Most materials will deform or break under heavy loads or pressures. This strength allows for the manufacture of highly functional machinery parts and structures with Monel 400, making them less susceptible to part damage that could lead to more frequent replacement cycles in the long run. - Thermal Stability :

The thermal properties of Monel 400 are also beneficial for a variety of industrial applications. It has good thermal conductivity, allowing it to transfer heat efficiently, and a low coefficient of expansion, ensuring it remains stable across varying temperatures. This stability is crucial in environments with fluctuating temperatures, such as processing plants and power generation facilities, where performance must be consistent without expansion or contraction. - Hydrofluoric Acid Resistance :

One of the key benefits associated with Monel 400 is its resistance to hydrofluoric acid, one of the most aggressive chemicals that can corrode nearly every other metal instantly. Its resistance to varying densities and temperatures of hydrofluoric acid makes it invaluable in the petrochemical industry, especially in HF processing. Monel 400’s resistance prevents rapid equipment degradation, allowing for safer and more efficient operations in harsh chemical environments

.

Practical Uses of Monel 400 Bands

The versatility of Monel 400 Bands makes them applicable in numerous industrial sectors. Here are some key areas where their attributes are particularly beneficial

- Marine Engineering : Monel 400’s resistance to salt water makes it perfect for marine applications, including shipbuilding and repair, where it is used for piping systems, pump shafts, and seawater valves.

- Chemical Processing : The alloy’s resistance to a wide range of chemicals allows for its use in reactors, heat exchangers, and transfer piping in chemical plants.

- Oil and Gas : In the oil and gas industry, Monel 400 is used for offshore drilling rigs, especially in components like drill collars and oil well tools that are exposed to highly corrosive environments.

- Power Generation : Its excellent thermal stability qualifies Monel 400 for applications in power plants where it is used in boiler feed water heaters and other high-temperature systems.

- Aerospace : The aerospace industry values Monel 400 for its high strength-to-weight ratio, utilizing it in airframe components and space craft parts that require minimal maintenance yet offer long service life.

Conclusion

Monel 400 Bands Stockist, Alloyed Sustainables, provides these versatile bands which are not only crucial for current industrial applications but are also paving the way for innovations in corrosion resistance technology. As industries continue to evolve and face new challenges, the reliability and versatility of Monel 400 Bands will remain in high demand, ensuring operational efficiency and integrity in harsh environments

For more information on our products and how they can benefit your industry Contact Alloyed Sustainables today at sales@alloyedsustainable.com your trusted Monel 400 Bands stockist and importer