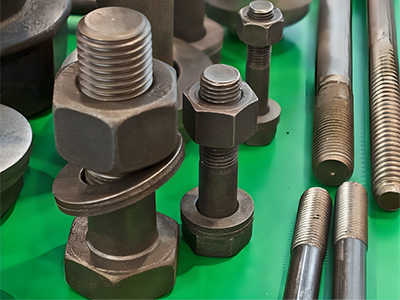

STUD

Alloyed Sustainables LLP is a distinguished exporter, stockist, and supplier of high-quality Stud Fasteners in Mumbai. Committed to excellence, the company emphasizes precision manufacturing and stringent quality control to meet both national and international standards. Our range of Stud Fasteners comes in a diverse materials range such as Monel, Hastelloy, Stainless Steel, etc that caters to various industries, showcasing their capability to address unique needs.

With advanced facilities and skilled artisans, Alloyed Sustainables LLP produces mechanically robust and corrosion-resistant fasteners. Our customer-centric approach involves exceptional support, timely deliveries, and tailored solutions, fostering enduring client relationships.

Description:

Stud fasteners, commonly known as studs, are components used in various industries, including construction, manufacturing, automotive, and fashion, to join two or more parts together securely. They are designed to provide a threaded post or rod that can be inserted into a pre-drilled hole or tapped threaded hole. Alloyed Sustainables LLP, a renowned market leader, offers a selection of fasteners including ASTM A193 B7 SS Stud Bolts, all available in a comprehensive range of sizes and shapes. Our factory produces a diverse range of studs available in various sizes and shapes. These bolts are crafted from premium materials, which have undergone quenching and tempering processes to enhance its strength.

Key Features of Studs:

- Double-Ended Threads: Studs possess threaded ends on both sides, allowing for the simultaneous attachment of two components without the need for nuts.

- Load Distribution: By distributing loads uniformly along their length, studs minimize stress concentrations on connected parts, enhancing overall structural integrity.

- Flush Installation: Studs can be installed in a way that their heads are flush or nearly flush with the surface, offering both a clean appearance and reduced risk of interference.

- Material Variety: Available in a wide array of materials, including stainless steel, carbon steel, aluminum, and brass, allowing selection based on factors like corrosion resistance and load requirements.

- Versatility: Found in various industries, studs serve not only functional purposes but also aesthetic ones, suitable for applications requiring both secure connections and visual appeal.

- Welding Capability: Certain stud types are designed for welding, enabling permanent and robust attachment through welding processes.

Application across Industries:

- Oil and Gas: Studs are employed in the oil and gas sector for connecting pipeline components, valves, and fittings in both onshore and offshore applications.

- Railway and Transportation:Studs are used in the railway industry for attaching rails and tracks, ensuring safe and smooth transportation.

- Marine: Studs contribute to marine applications by providing secure connections in shipbuilding, offshore structures, and underwater equipment.

- Energy Sector: Studs are utilized in power generation and distribution equipment, including turbines and transformers, where secure connections are crucial for reliable operation.

- Automotive: Studs are employed in engine components, exhaust systems, and chassis assemblies, providing reliable fastening and alignment in critical areas.

Studs are available in a diverse selection of materials and varying levels of quality, each tailored to fulfill the distinct needs of particular markets.

STANDARD SPECIFICATION

- DIN STANDARD: B.S. DIN 933, DIN 931, DIN 934, DIN 912, DIN 603, DIN 6923, DIN 970, DIN 7981, DIN 7982, DIN916, DIN 913, DIN 7985

- SIZE: M10 – M100

- LENGTH: 3 mm to 200 mm

- STAINLESS STEEL: AISI 302, 304, 304L, 316, 316L, 310, 317, 316S31, 317L, 321, 347, 410, 420,904L,ALLOY 20 etc.

- DUPLEX & SUPER DUPLEX STEEL: ASTM / ASME A815 UNS No. S31803, UNS No. S 32205, UNS No. S 31254, UNS No. S 31550, UNS No. S 32750, and UNS No. S 32760.

- CARBON STEEL: ASTM A307, A193

- ALLOY STEEL: ASTM / ASME A/SA 193 / 194 B 6, B 7/ B 7M, B 16, 2, 2HM, 2H, GR 6, B 7, B 7M.

- NICKEL ALLOY: ASTM / ASME SB 160 / 164 / 425 / 166 / 446 / 574 / 472 UNS 2200 (NICKEL 200) / UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400), UNS 8825 (INCONEL 825), UNS 6600 (INCONEL 600) / UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276), UNS 8020 ( 20 CB 3)

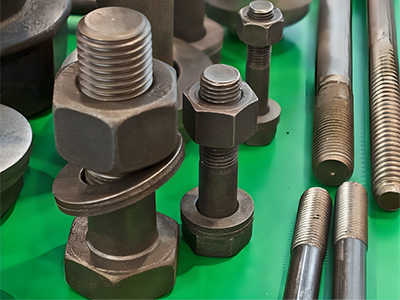

STUD

Alloyed Sustainables LLP is a distinguished exporter, stockist, and supplier of high-quality Stud Fasteners in Mumbai. Committed to excellence, the company emphasizes precision manufacturing and stringent quality control to meet both national and international standards. Our range of Stud Fasteners comes in a diverse materials range such as Monel, Hastelloy, Stainless Steel, etc that caters to various industries, showcasing their capability to address unique needs.

With advanced facilities and skilled artisans, Alloyed Sustainables LLP produces mechanically robust and corrosion-resistant fasteners. Our customer-centric approach involves exceptional support, timely deliveries, and tailored solutions, fostering enduring client relationships.

Description:

Stud fasteners, commonly known as studs, are components used in various industries, including construction, manufacturing, automotive, and fashion, to join two or more parts together securely. They are designed to provide a threaded post or rod that can be inserted into a pre-drilled hole or tapped threaded hole. Alloyed Sustainables LLP, a renowned market leader, offers a selection of fasteners including ASTM A193 B7 SS Stud Bolts, all available in a comprehensive range of sizes and shapes. Our factory produces a diverse range of studs available in various sizes and shapes. These bolts are crafted from premium materials, which have undergone quenching and tempering processes to enhance its strength.

Key Features of Studs:

- Double-Ended Threads: Studs possess threaded ends on both sides, allowing for the simultaneous attachment of two components without the need for nuts.

- Load Distribution: By distributing loads uniformly along their length, studs minimize stress concentrations on connected parts, enhancing overall structural integrity.

- Flush Installation: Studs can be installed in a way that their heads are flush or nearly flush with the surface, offering both a clean appearance and reduced risk of interference.

- Material Variety: Available in a wide array of materials, including stainless steel, carbon steel, aluminum, and brass, allowing selection based on factors like corrosion resistance and load requirements.

- Versatility: Found in various industries, studs serve not only functional purposes but also aesthetic ones, suitable for applications requiring both secure connections and visual appeal.

- Welding Capability: Certain stud types are designed for welding, enabling permanent and robust attachment through welding processes.

Application across Industries:

- Oil and Gas: Studs are employed in the oil and gas sector for connecting pipeline components, valves, and fittings in both onshore and offshore applications.

- Railway and Transportation:Studs are used in the railway industry for attaching rails and tracks, ensuring safe and smooth transportation.

- Marine: Studs contribute to marine applications by providing secure connections in shipbuilding, offshore structures, and underwater equipment.

- Energy Sector: Studs are utilized in power generation and distribution equipment, including turbines and transformers, where secure connections are crucial for reliable operation.

- Automotive: Studs are employed in engine components, exhaust systems, and chassis assemblies, providing reliable fastening and alignment in critical areas.

Studs are available in a diverse selection of materials and varying levels of quality, each tailored to fulfill the distinct needs of particular markets.

STANDARD SPECIFICATION

- DIN STANDARD: B.S. DIN 933, DIN 931, DIN 934, DIN 912, DIN 603, DIN 6923, DIN 970, DIN 7981, DIN 7982, DIN916, DIN 913, DIN 7985

- SIZE: M10 – M100

- LENGTH: 3 mm to 200 mm

- STAINLESS STEEL: AISI 302, 304, 304L, 316, 316L, 310, 317, 316S31, 317L, 321, 347, 410, 420,904L,ALLOY 20 etc.

- DUPLEX & SUPER DUPLEX STEEL: ASTM / ASME A815 UNS No. S31803, UNS No. S 32205, UNS No. S 31254, UNS No. S 31550, UNS No. S 32750, and UNS No. S 32760.

- CARBON STEEL: ASTM A307, A193

- ALLOY STEEL: ASTM / ASME A/SA 193 / 194 B 6, B 7/ B 7M, B 16, 2, 2HM, 2H, GR 6, B 7, B 7M.

- NICKEL ALLOY: ASTM / ASME SB 160 / 164 / 425 / 166 / 446 / 574 / 472 UNS 2200 (NICKEL 200) / UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400), UNS 8825 (INCONEL 825), UNS 6600 (INCONEL 600) / UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276), UNS 8020 ( 20 CB 3)