FORGED FITTINGS

Alloyed Sustainables LLP specializes in providing high-quality forged fittings that meet the needs of various industries. As importers and stockists of Forged fittings, we understand the importance of these components in piping systems.

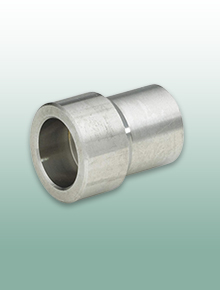

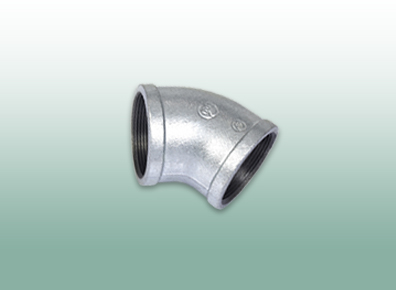

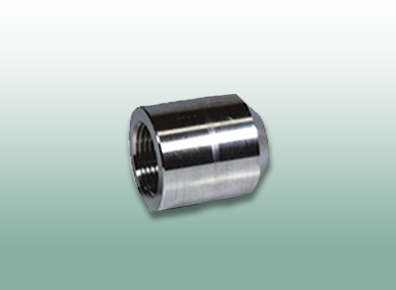

Forged fittings are robust components used to connect, terminate, divert, or change the direction of pipes in a piping system. These fittings undergo a forging process that subjects a solid metal piece to extreme heat and pressure, resulting in exceptional strength and durability. This strength allows forged fittings to excel in high-pressure, high-temperature, and corrosive environments.

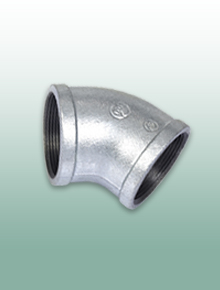

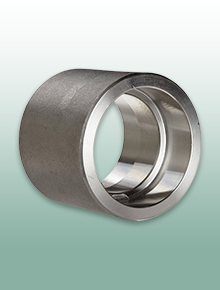

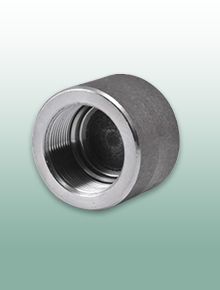

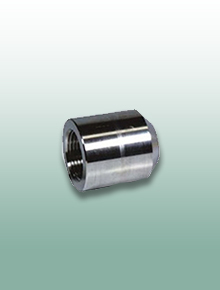

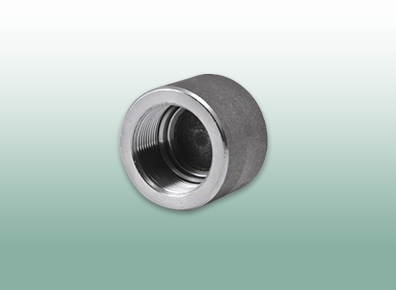

Our forged fittings are available in a wide range of product grades to meet the specific requirements of your applications. These grades such 45’ degree elbow, 90’ elbow, Tee, Union Tee, Coupling, Swage Nipple, Bushing, Plug etc. are carefully selected to ensure that the fittings perform exceptionally well in various environments and conditions.

Bushing

Key Characteristics of Forged Fittings:

- Durability: Forged fittings are renowned for their longevity and reliability.

- High Pressure Resistance: These fittings are capable of withstanding high-pressure conditions.

- Resistance to Corrosion: Made from materials like stainless steel, they offer excellent corrosion resistance.

- Precision: The forging process ensures precise dimensions.

- Enhanced Strength: The grain structure of forged fittings optimizes strength and impact resistance

- Oil and Gas: Handling high pressure and corrosive environments.

- Chemical: Resisting harsh chemicals in processing plants.

- Power Generation: Managing high-temperature and high-pressure steam and gases.

- Petrochemical: Coping with extreme temperatures and chemicals.

- Water Treatment: Facilitating water distribution and sewage systems.

Forged fittings find APPLICATIONS in diverse industries, including:

As your trusted source for Forged fittings located in Mumbai, India , we recognize their importance in various industrial settings. Importers and stockists of forged fittings, we ensure that you have access to the highest quality components, along with a diverse product grade range to meet your specific needs.

For industries ranging from oil and gas to water treatment, these fittings are indispensable for maintaining the integrity of your piping systems.

Feel free to explore our range of forged fittings and discover the reliability and durability that has made us a preferred choice for professionals across industries.

faq's

Forged pipe fittings are essential components used in piping systems to connect, redirect, or close the flow of fluids in various industrial, commercial, and residential applications.

Forged pipe fittings are manufactured through the forging process, which involves heating metal and shaping it using pressure to form the desired fitting shapes and structures.

Forged pipe fittings are typically made from materials such as carbon steel, stainless steel, alloy steel, brass, and other metals, chosen based on factors like application requirements, corrosion resistance, and strength.

Forged pipe fittings find applications in various industries, including oil and gas, chemical processing, power generation, water treatment, construction, and plumbing, where they are crucial for creating a reliable piping infrastructure.

Common types of forged pipe fittings include elbows (45° and 90°), tees, reducers, couplings, caps, and unions, each serving specific purposes like changing direction, splitting flow, joining pipes, sealing ends, and allowing easy disconnection.

The selection of forged pipe fittings depends on factors such as the type of fluid, pressure and temperature requirements, pipe size, and the layout of the piping system. Consulting with professionals can help in making informed decisions.

Yes, forged pipe fittings are designed to handle a wide range of pressure levels, making them suitable for both high-pressure and low-pressure applications based on the specific fitting and material used.

Forged pipe fittings can generally be reused if they are in good condition and have not undergone any deformations or damages during their previous use. Proper inspection is crucial before reuse.

Forged pipe fittings are created through the forging process, resulting in higher strength and better quality, whereas cast pipe fittings are made by pouring molten metal into molds, typically offering lower strength compared to forged fittings.

Regular maintenance, inspection for signs of wear or corrosion, and proper installation are key to ensuring the longevity of forged pipe fittings. Addressing any issues promptly and using compatible materials are also important factors.