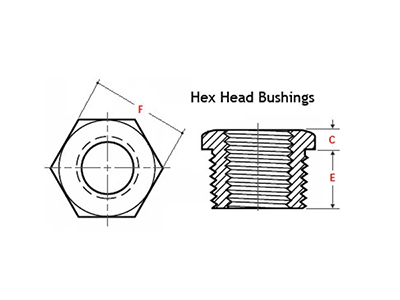

BUSHING

Alloyed Sustainables LLP excels as a premier supplier, manufacturer, and exporter of a comprehensive variety of top-notch forged bushings, available at competitive rates. Our exceptional bushings garner attention from a diverse range of customers. Meeting distinct specifications, we provide a selection of premium-grade bushings in both standard and customizable designs. Drawing on extensive industry knowledge, we meticulously craft these bushings in strict accordance with worldwide industry benchmarks.

Description:

In piping systems, bushing forged fittings are used to connect pipes of differing diameters. They are designed to alter the diameter of the conduit and typically consist of a circular piece with threaded ends for simple installation. The oil and gas, industrial, chemical, and power generation industries, among others, frequently utilize bushing forged fittings. These bushings can be manufactured in a variety of sizes, materials, grades, and specifications to satisfy the requirements of various clients and businesses.

Key Features of Forged Bushing:

- Material Strength: Forged from robust materials like alloyed steel or stainless steel, ensuring high pressure and mechanical stress resistance.

- Durability: Endures extreme conditions without deformation, suitable for high temperatures, corrosive environments, and heavy loads.

- Pressure Resistance: Designed to maintain integrity under high pressure, making them vital for hydraulic systems, pipelines, and chemical plants.

- Threaded Ends: Equipped with threaded ends for secure installation into pipes, valves, or fittings, preventing leaks and enabling easy setup.

- Size Transition: Available as reducing or expanding types, allowing seamless connection between pipes of varying sizes.

Application across Industries:

- Oil and Gas: Used in pipelines and refinery equipment for connecting different pipe sizes and withstanding high pressures and harsh conditions.

- Chemical Processing: Employed in corrosive environments where chemical-resistant materials are crucial for maintaining safe and efficient connections.

- Power Generation: Utilized in power plants to connect pipes in steam, water, and cooling systems, offering durability and pressure resistance.

- Marine: Vital in marine applications, connecting pipes for water, fuel, and other fluids while withstanding corrosive saltwater environments.

Created from a wide variety of materials and grades, our Forged Bushings are manufactured to meet the unique requirements of clients spanning a broad range of industries.

STAINLESS STEEL & DUPLEX STEEL BUSHINGS:

Specifications:

- Size : 1/2″ NB to 4″ NB, (Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Stainless Steel : ASTM A 182 F – 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A 182 F -51,F 53, F 55

ALLOY STEEL, CARBON STEEL & LTCS BUSHINGS:

Specifications:

- Size : 1/2″ NB to 4″ NB, (Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Alloy Steel : ASTM A 182-F5,F9,F11,F21,F22 & F91

- Carbon Steel : ASTM A 105

- Low Temperature Carbon Steel : A 350 LF2

- Other Services : Hot Dip Galvanizing, Sand Blasting, Customized Machining

COPPER & NICKEL ALLOYS BUSHINGS:

Specifications:

- Size : 1/2″ NB to 4″ NB(Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400, N05500

- Inconel : UNS N06600, N06601, N06625, N08800, N08810, N08825,

- Hastelloy : UNS N10276, N06022, N10665, N06455,

- Titanium : Gr. 1,2.3, DTH 3.7025, DTH 3.7035, DTH 3.7055

- SMO 254 : UNS S31254

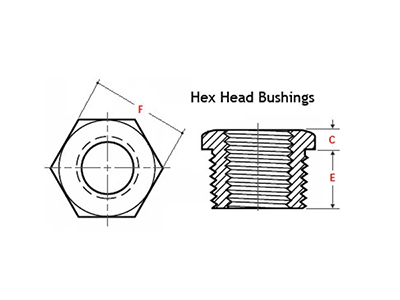

BUSHING

Alloyed Sustainables LLP excels as a premier supplier, manufacturer, and exporter of a comprehensive variety of top-notch forged bushings, available at competitive rates. Our exceptional bushings garner attention from a diverse range of customers. Meeting distinct specifications, we provide a selection of premium-grade bushings in both standard and customizable designs. Drawing on extensive industry knowledge, we meticulously craft these bushings in strict accordance with worldwide industry benchmarks.

Description:

In piping systems, bushing forged fittings are used to connect pipes of differing diameters. They are designed to alter the diameter of the conduit and typically consist of a circular piece with threaded ends for simple installation. The oil and gas, industrial, chemical, and power generation industries, among others, frequently utilize bushing forged fittings. These bushings can be manufactured in a variety of sizes, materials, grades, and specifications to satisfy the requirements of various clients and businesses.

Key Features of Forged Bushing:

- Material Strength: Forged from robust materials like alloyed steel or stainless steel, ensuring high pressure and mechanical stress resistance.

- Durability: Endures extreme conditions without deformation, suitable for high temperatures, corrosive environments, and heavy loads.

- Pressure Resistance: Designed to maintain integrity under high pressure, making them vital for hydraulic systems, pipelines, and chemical plants.

- Threaded Ends: Equipped with threaded ends for secure installation into pipes, valves, or fittings, preventing leaks and enabling easy setup.

- Size Transition: Available as reducing or expanding types, allowing seamless connection between pipes of varying sizes.

Application across Industries:

- Oil and Gas: Used in pipelines and refinery equipment for connecting different pipe sizes and withstanding high pressures and harsh conditions.

- Chemical Processing: Employed in corrosive environments where chemical-resistant materials are crucial for maintaining safe and efficient connections.

- Power Generation: Utilized in power plants to connect pipes in steam, water, and cooling systems, offering durability and pressure resistance.

- Marine: Vital in marine applications, connecting pipes for water, fuel, and other fluids while withstanding corrosive saltwater environments.

Created from a wide variety of materials and grades, our Forged Bushings are manufactured to meet the unique requirements of clients spanning a broad range of industries.

STAINLESS STEEL & DUPLEX STEEL BUSHINGS:

Specifications:

- Size : 1/2″ NB to 4″ NB, (Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Stainless Steel : ASTM A 182 F – 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A 182 F -51,F 53, F 55

ALLOY STEEL, CARBON STEEL & LTCS BUSHINGS:

Specifications:

- Size : 1/2″ NB to 4″ NB, (Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Alloy Steel : ASTM A 182-F5,F9,F11,F21,F22 & F91

- Carbon Steel : ASTM A 105

- Low Temperature Carbon Steel : A 350 LF2

- Other Services : Hot Dip Galvanizing, Sand Blasting, Customized Machining

COPPER & NICKEL ALLOYS BUSHINGS:

Specifications:

- Size : 1/2″ NB to 4″ NB(Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400, N05500

- Inconel : UNS N06600, N06601, N06625, N08800, N08810, N08825,

- Hastelloy : UNS N10276, N06022, N10665, N06455,

- Titanium : Gr. 1,2.3, DTH 3.7025, DTH 3.7035, DTH 3.7055

- SMO 254 : UNS S31254