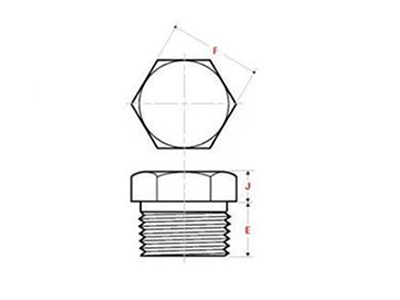

PLUG

Alloyed Sustainables stands as a prominent manufacturer of top-tier Forged Plugs. Our Forged Plugs undergo meticulous production using premium materials, guaranteeing exceptional functionality and prolonged service life. Rooted in our core values, an unwavering commitment to customer satisfaction drives our endeavours, establishing the foundation upon which we foster robust partnerships with clients to not only fulfil but exceed their anticipations.

Description:

Forged Plugs are a type of pipe fitting used in various industries to create temporary or permanent seals in pipelines. These fittings are typically used in high-pressure applications where a tight and reliable connection is essential. They are designed to close off the end of a pipe or fitting, effectively plugging the flow of liquids or gases. Forged Plugs have widespread applications, including sealing pipelines in oil and gas, maintaining equipment in petrochemical plants, and closing steam and water lines in power generation.

Key Features of Forged Plugs:

- Material: Forged plugs are made from durable materials like carbon steel, stainless steel, or brass to withstand corrosion and maintain strength in various conditions.

- Pressure Rating: Designed for high-pressure environments, forged plugs are available in different pressure ratings to ensure safe and reliable sealing in demanding applications.

- Size Range: With various sizes offered, forged plugs accommodate different pipe diameters and thread specifications for proper fit within piping systems.

- Types: Threaded plugs, featuring male threads, and socket weld plugs, inserted into socket-weld fittings, offer secure sealing methods for both low and high-pressure systems.

- Design: Forged plugs typically feature hexagonal or square heads, allowing easy tightening and removal using wrenches, ensuring a secure connection and easy maintenance.

- Thread Specifications: Threaded forged plugs adhere to standards like NPT or BSP threads, ensuring compatibility with the threads of pipes or fittings.

Application across Industries:

- Marine: Forged plugs are employed in marine applications to close off sections of pipelines, tanks, and systems during maintenance, repairs, or upgrades.

- Water Treatment: Forged plugs are utilized in water treatment facilities to close off pipes and equipment during maintenance, ensuring efficient system operation.

- Chemical Processing: In chemical plants, forged plugs serve as temporary or permanent seals for reactors, storage tanks, and processing equipment during cleaning, inspection, or maintenance.

- Power Generation: Forged plugs are used in power plants to seal off steam and water lines, condensers, and heat exchangers, allowing maintenance without system shutdowns.

- Oil and Gas: In the oil and gas industry, forged plugs are used to seal off sections of pipelines, wellheads, and pressure vessels during maintenance or when rerouting flows.

Created from a wide variety of materials and grades, our Forged Plugs are customized to meet the unique requirements of clients spanning a broad range of industries.

STAINLESS STEEL & DUPLEX STEEL PLUGS:

Specifications:

- Size : 1/2″ NB to 4″ NB, (Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Stainless Steel : ASTM A 182 F – 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A 182 F -51,F 53, F 55

ALLOY STEEL, CARBON STEEL & LTCS PLUGS:

Specifications:

- Size : 1/2″ NB to 4″ NB, (Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Alloy Steel : ASTM A 182-F5,F9,F11,F21,F22 & F91

- Carbon Steel : ASTM A 105

- Low Temperature Carbon Steel : A 350 LF2

- Other Services : Hot Dip Galvanizing, Sand Blasting, Customized Machining

COPPER & NICKEL ALLOYS PLUGS:

Specifications:

- Size : 1/2″ NB to 4″ NB(Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400, N05500

- Inconel : UNS N06600, N06601, N06625, N08800, N08810, N08825,

- Hastelloy : UNS N10276, N06022, N10665, N06455,

- Titanium : Gr. 1,2.3, DTH 3.7025, DTH 3.7035, DTH 3.7055

- SMO 254 : UNS S31254

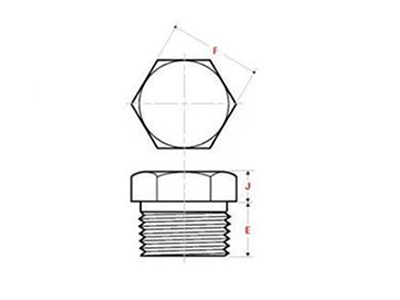

PLUG

Alloyed Sustainables stands as a prominent manufacturer of top-tier Forged Plugs. Our Forged Plugs undergo meticulous production using premium materials, guaranteeing exceptional functionality and prolonged service life. Rooted in our core values, an unwavering commitment to customer satisfaction drives our endeavours, establishing the foundation upon which we foster robust partnerships with clients to not only fulfil but exceed their anticipations.

Description:

Forged Plugs are a type of pipe fitting used in various industries to create temporary or permanent seals in pipelines. These fittings are typically used in high-pressure applications where a tight and reliable connection is essential. They are designed to close off the end of a pipe or fitting, effectively plugging the flow of liquids or gases. Forged Plugs have widespread applications, including sealing pipelines in oil and gas, maintaining equipment in petrochemical plants, and closing steam and water lines in power generation.

Key Features of Forged Plugs:

- Material: Forged plugs are made from durable materials like carbon steel, stainless steel, or brass to withstand corrosion and maintain strength in various conditions.

- Pressure Rating: Designed for high-pressure environments, forged plugs are available in different pressure ratings to ensure safe and reliable sealing in demanding applications.

- Size Range: With various sizes offered, forged plugs accommodate different pipe diameters and thread specifications for proper fit within piping systems.

- Types: Threaded plugs, featuring male threads, and socket weld plugs, inserted into socket-weld fittings, offer secure sealing methods for both low and high-pressure systems.

- Design: Forged plugs typically feature hexagonal or square heads, allowing easy tightening and removal using wrenches, ensuring a secure connection and easy maintenance.

- Thread Specifications: Threaded forged plugs adhere to standards like NPT or BSP threads, ensuring compatibility with the threads of pipes or fittings.

Application across Industries:

- Marine: Forged plugs are employed in marine applications to close off sections of pipelines, tanks, and systems during maintenance, repairs, or upgrades.

- Water Treatment: Forged plugs are utilized in water treatment facilities to close off pipes and equipment during maintenance, ensuring efficient system operation.

- Chemical Processing: In chemical plants, forged plugs serve as temporary or permanent seals for reactors, storage tanks, and processing equipment during cleaning, inspection, or maintenance.

- Power Generation: Forged plugs are used in power plants to seal off steam and water lines, condensers, and heat exchangers, allowing maintenance without system shutdowns.

- Oil and Gas: In the oil and gas industry, forged plugs are used to seal off sections of pipelines, wellheads, and pressure vessels during maintenance or when rerouting flows.

Created from a wide variety of materials and grades, our Forged Plugs are customized to meet the unique requirements of clients spanning a broad range of industries.

STAINLESS STEEL & DUPLEX STEEL PLUGS:

Specifications:

- Size : 1/2″ NB to 4″ NB, (Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Stainless Steel : ASTM A 182 F – 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A 182 F -51,F 53, F 55

ALLOY STEEL, CARBON STEEL & LTCS PLUGS:

Specifications:

- Size : 1/2″ NB to 4″ NB, (Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Alloy Steel : ASTM A 182-F5,F9,F11,F21,F22 & F91

- Carbon Steel : ASTM A 105

- Low Temperature Carbon Steel : A 350 LF2

- Other Services : Hot Dip Galvanizing, Sand Blasting, Customized Machining

COPPER & NICKEL ALLOYS PLUGS:

Specifications:

- Size : 1/2″ NB to 4″ NB(Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400, N05500

- Inconel : UNS N06600, N06601, N06625, N08800, N08810, N08825,

- Hastelloy : UNS N10276, N06022, N10665, N06455,

- Titanium : Gr. 1,2.3, DTH 3.7025, DTH 3.7035, DTH 3.7055

- SMO 254 : UNS S31254