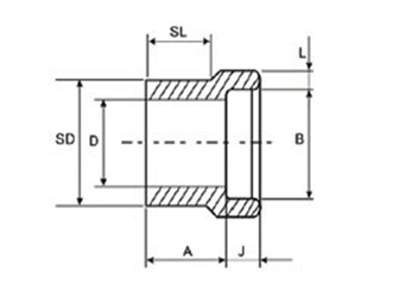

INSERT

Alloyed Sustainables LLP is fully committed to producing top-notch Forged Inserts that impeccably align with the unique requirements of our esteemed customers. Our Threaded Inserts are intricately crafted to meet specific benchmarks, ensuring their smooth incorporation into a variety of piping networks. Our resolute dedication involves utilizing only the finest materials throughout the manufacturing procedure, resulting in Forged Inserts that stand out due to exceptional robustness, prolonged usefulness, and accurate dimensions.

Description:

Forged fittings inserts, often referred to simply as “inserts,” are components used in piping systems to provide a threaded connection point for joining pipes, valves, and other equipment. These inserts are usually made from high-strength materials through a forging process, which imparts excellent mechanical properties and durability to the fittings. There are various types of forged fittings inserts, including threaded inserts, socket weld inserts, and weldolet inserts. Each type is designed for a specific type of connection method and application. Forged fittings inserts play a crucial role in various industries, including oil and gas, petrochemicals, power generation, and more.

Key Features of Forged Inserts:

- Material Strength: Made from strong materials like stainless steel, carbon steel, and alloys for withstanding high pressures.

- Durability: Forging process aligns grain structure, enhancing resilience against stress and wear.

- Corrosion Resistance: Materials chosen to resist corrosion in various environments.

- Leak Resistance: Precise threading creates secure joints, preventing fluid or gas leaks.

- Thread Accuracy: Well-machined threads ensure consistent and reliable connections.

- Compatibility: Fits with diverse pipes, valves, and fittings, allowing flexibility.

Application across Industries:

- Oil and Gas: Used in pipelines, refineries, and drilling operations for secure connections in harsh conditions.

- Power Generation: Ensure leak-free connections in steam and gas lines, enhancing safety in power plants.

- Chemical Processing: Handle various chemicals with corrosion-resistant inserts, maintaining process integrity.

- Water Treatment: Used for water transport and treatment systems, maintaining fluid purity.

- Marine: Withstand saltwater exposure in shipbuilding and offshore structures.

Created from a wide variety of materials and grades, our forged inserts are customized to meet the unique requirements of clients spanning a broad range of industries.

STAINLESS STEEL & DUPLEX STEEL INSERTS:

Specifications:

- Size : 1/2″ NB to 4″ NB, (Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Stainless Steel : ASTM A 182 F – 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A 182 F -51,F 53, F 55

ALLOY STEEL, CARBON STEEL & LTCS INSERTS:

Specifications:

- Size : 1/2″ NB to 4″ NB, (Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Alloy Steel : ASTM A 182-F5,F9,F11,F21,F22 & F91

- Carbon Steel : ASTM A 105

- Low Temperature Carbon Steel : A 350 LF2

- Other Services : Hot Dip Galvanizing, Sand Blasting, Customized Machining

COPPER & NICKEL ALLOYS INSERTS:

Specifications:

- Size : 1/2″ NB to 4″ NB(Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400, N05500

- Inconel : UNS N06600, N06601, N06625, N08800, N08810, N08825,

- Hastelloy : UNS N10276, N06022, N10665, N06455,

- Titanium : Gr. 1,2.3, DTH 3.7025, DTH 3.7035, DTH 3.7055

- SMO 254 : UNS S31254

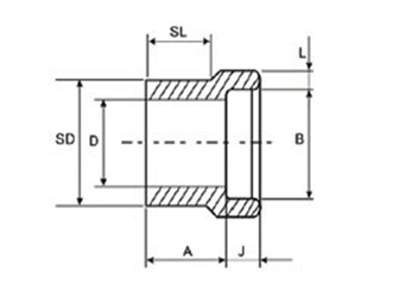

INSERT

Alloyed Sustainables LLP is fully committed to producing top-notch Forged Inserts that impeccably align with the unique requirements of our esteemed customers. Our Threaded Inserts are intricately crafted to meet specific benchmarks, ensuring their smooth incorporation into a variety of piping networks. Our resolute dedication involves utilizing only the finest materials throughout the manufacturing procedure, resulting in Forged Inserts that stand out due to exceptional robustness, prolonged usefulness, and accurate dimensions.

Description:

Forged fittings inserts, often referred to simply as “inserts,” are components used in piping systems to provide a threaded connection point for joining pipes, valves, and other equipment. These inserts are usually made from high-strength materials through a forging process, which imparts excellent mechanical properties and durability to the fittings. There are various types of forged fittings inserts, including threaded inserts, socket weld inserts, and weldolet inserts. Each type is designed for a specific type of connection method and application. Forged fittings inserts play a crucial role in various industries, including oil and gas, petrochemicals, power generation, and more.

Key Features of Forged Inserts:

- Material Strength: Made from strong materials like stainless steel, carbon steel, and alloys for withstanding high pressures.

- Durability: Forging process aligns grain structure, enhancing resilience against stress and wear.

- Corrosion Resistance: Materials chosen to resist corrosion in various environments.

- Leak Resistance: Precise threading creates secure joints, preventing fluid or gas leaks.

- Thread Accuracy: Well-machined threads ensure consistent and reliable connections.

- Compatibility: Fits with diverse pipes, valves, and fittings, allowing flexibility.

Application across Industries:

- Oil and Gas: Used in pipelines, refineries, and drilling operations for secure connections in harsh conditions.

- Power Generation: Ensure leak-free connections in steam and gas lines, enhancing safety in power plants.

- Chemical Processing: Handle various chemicals with corrosion-resistant inserts, maintaining process integrity.

- Water Treatment: Used for water transport and treatment systems, maintaining fluid purity.

- Marine: Withstand saltwater exposure in shipbuilding and offshore structures.

Created from a wide variety of materials and grades, our forged inserts are customized to meet the unique requirements of clients spanning a broad range of industries.

STAINLESS STEEL & DUPLEX STEEL INSERTS:

Specifications:

- Size : 1/2″ NB to 4″ NB, (Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Stainless Steel : ASTM A 182 F – 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A 182 F -51,F 53, F 55

ALLOY STEEL, CARBON STEEL & LTCS INSERTS:

Specifications:

- Size : 1/2″ NB to 4″ NB, (Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Alloy Steel : ASTM A 182-F5,F9,F11,F21,F22 & F91

- Carbon Steel : ASTM A 105

- Low Temperature Carbon Steel : A 350 LF2

- Other Services : Hot Dip Galvanizing, Sand Blasting, Customized Machining

COPPER & NICKEL ALLOYS INSERTS:

Specifications:

- Size : 1/2″ NB to 4″ NB(Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400, N05500

- Inconel : UNS N06600, N06601, N06625, N08800, N08810, N08825,

- Hastelloy : UNS N10276, N06022, N10665, N06455,

- Titanium : Gr. 1,2.3, DTH 3.7025, DTH 3.7035, DTH 3.7055

- SMO 254 : UNS S31254