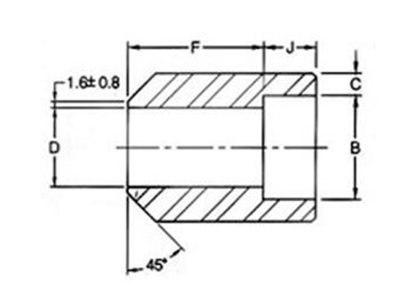

BOSS

Alloyed Sustainables LLP stands as a highly reliable manufacturer and exporter of a diverse range of Forged Boss fittings. We are dedicated to addressing the requirements of our esteemed customers, providing boss fittings in an extensive array of Sizes, Grades, and Specifications. Ensuring customer contentment is fundamental to our operations. Our commitment lies in delivering precisely engineered Forged Boss fittings that exhibit exceptional precision and effectiveness, all while maintaining our competitiveness in pricing.

Description:

Boss Forged Fittings are components used in piping and plumbing systems to connect, control, and adapt the flow of fluids (liquids or gases) within pipelines. These fittings are typically made from high-quality materials through forging processes, which involve shaping metal under high pressure and heat to enhance strength and durability. The term “boss” in this context refers to a protruding part of the fitting that allows for the connection of other components. Forged fittings are preferred in various applications due to their superior strength and resistance to pressure, temperature, and corrosion.

Key Features of Forged Boss:

- Strength & Durability: Forged under high pressure and heat, these fittings boast exceptional strength and durability for demanding high-pressure environments.

- Leak-Proof Design: Precise construction ensures tight connections, minimizing leaks and preserving system integrity.

- High Pressure Resilience: Engineered to withstand the rigors of high-pressure applications in industries like oil and gas.

- Temperature Range: Capable of functioning across a broad temperature spectrum, adapting to varying conditions.

- Ease of Installation: Socket weld and threaded connections simplify installation and maintenance processes.

Application across Industries:

- Oil and Gas: Used extensively in pipelines and equipment for transporting oil, gas, and other hydrocarbons due to their high-pressure resistance and corrosion resilience.

- Power Generation: Employed in power plants for water, steam, and coolant systems, coping with varying pressures and temperatures.

- Chemical Processing: Their corrosion resistance and material compatibility make them essential in handling various chemicals.

- Water Treatment: In water and wastewater treatment facilities, these fittings endure exposure to chemicals, high pressures, and temperature fluctuations.

- Marine: Vital in maritime applications for their resistance to saltwater corrosion and ability to handle different fluids.

Manufactured using an extensive array of materials and grades, our boss forged fittings are tailored to fulfil the distinct needs of clients spanning a diverse array of industries.

STAINLESS STEEL & DUPLEX STEEL BOSS:

Specifications:

- Size : 1/2″ NB to 4″ NB, (Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Stainless Steel : ASTM A 182 F – 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A 182 F -51,F 53, F 55

ALLOY STEEL, CARBON STEEL & LTCS BOSS:

Specifications:

- Size : 1/2″ NB to 4″ NB, (Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Alloy Steel : ASTM A 182-F5,F9,F11,F21,F22 & F91

- Carbon Steel : ASTM A 105

- Low Temperature Carbon Steel : A 350 LF2

- Other Services : Hot Dip Galvanizing, Sand Blasting, Customized Machining

COPPER & NICKEL ALLOYS BOSS:

Specifications:

- Size : 1/2″ NB to 4″ NB(Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400, N05500

- Inconel : UNS N06600, N06601, N06625, N08800, N08810, N08825,

- Hastelloy : UNS N10276, N06022, N10665, N06455,

- Titanium : Gr. 1,2.3, DTH 3.7025, DTH 3.7035, DTH 3.7055

- SMO 254 : UNS S31254

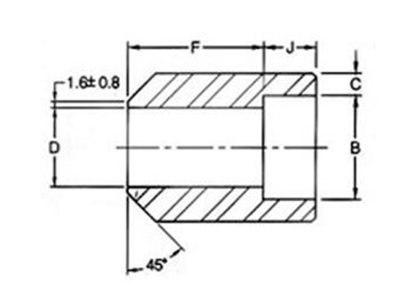

BOSS

Alloyed Sustainables LLP stands as a highly reliable manufacturer and exporter of a diverse range of Forged Boss fittings. We are dedicated to addressing the requirements of our esteemed customers, providing boss fittings in an extensive array of Sizes, Grades, and Specifications. Ensuring customer contentment is fundamental to our operations. Our commitment lies in delivering precisely engineered Forged Boss fittings that exhibit exceptional precision and effectiveness, all while maintaining our competitiveness in pricing.

Description:

Boss Forged Fittings are components used in piping and plumbing systems to connect, control, and adapt the flow of fluids (liquids or gases) within pipelines. These fittings are typically made from high-quality materials through forging processes, which involve shaping metal under high pressure and heat to enhance strength and durability. The term “boss” in this context refers to a protruding part of the fitting that allows for the connection of other components. Forged fittings are preferred in various applications due to their superior strength and resistance to pressure, temperature, and corrosion.

Key Features of Forged Boss:

- Strength & Durability: Forged under high pressure and heat, these fittings boast exceptional strength and durability for demanding high-pressure environments.

- Leak-Proof Design: Precise construction ensures tight connections, minimizing leaks and preserving system integrity.

- High Pressure Resilience: Engineered to withstand the rigors of high-pressure applications in industries like oil and gas.

- Temperature Range: Capable of functioning across a broad temperature spectrum, adapting to varying conditions.

- Ease of Installation: Socket weld and threaded connections simplify installation and maintenance processes.

Application across Industries:

- Oil and Gas: Used extensively in pipelines and equipment for transporting oil, gas, and other hydrocarbons due to their high-pressure resistance and corrosion resilience.

- Power Generation: Employed in power plants for water, steam, and coolant systems, coping with varying pressures and temperatures.

- Chemical Processing: Their corrosion resistance and material compatibility make them essential in handling various chemicals.

- Water Treatment: In water and wastewater treatment facilities, these fittings endure exposure to chemicals, high pressures, and temperature fluctuations.

- Marine: Vital in maritime applications for their resistance to saltwater corrosion and ability to handle different fluids.

Manufactured using an extensive array of materials and grades, our boss forged fittings are tailored to fulfil the distinct needs of clients spanning a diverse array of industries.

STAINLESS STEEL & DUPLEX STEEL BOSS:

Specifications:

- Size : 1/2″ NB to 4″ NB, (Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Stainless Steel : ASTM A 182 F – 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A 182 F -51,F 53, F 55

ALLOY STEEL, CARBON STEEL & LTCS BOSS:

Specifications:

- Size : 1/2″ NB to 4″ NB, (Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Alloy Steel : ASTM A 182-F5,F9,F11,F21,F22 & F91

- Carbon Steel : ASTM A 105

- Low Temperature Carbon Steel : A 350 LF2

- Other Services : Hot Dip Galvanizing, Sand Blasting, Customized Machining

COPPER & NICKEL ALLOYS BOSS:

Specifications:

- Size : 1/2″ NB to 4″ NB(Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400, N05500

- Inconel : UNS N06600, N06601, N06625, N08800, N08810, N08825,

- Hastelloy : UNS N10276, N06022, N10665, N06455,

- Titanium : Gr. 1,2.3, DTH 3.7025, DTH 3.7035, DTH 3.7055

- SMO 254 : UNS S31254