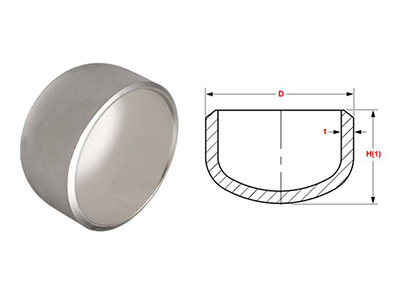

CAP

Alloyed Sustainables LLP is a distinguished Manufacturer of Forged Caps. Our products are meticulously crafted from premium materials in adherence to international standards, our forged caps epitomize unparalleled quality and reliability. Our steadfast commitment to excellence guarantees that you receive only the finest products, providing secure and dependable solutions that cater to a wide array of industries.

Description:

Forged caps, also referred to as forged pipe caps or forged end caps, serve as vital elements within piping systems, tasked with effectively sealing the termination of a pipe. Designed meticulously, these fittings encapsulate the exposed end of a pipe or tube, imparting a resilient shield that halts the passage of fluids or gases. Their widespread application spans diverse sectors, encompassing industries like oil and gas, petrochemicals, chemicals, power generation, and beyond.

Key Features of Forged Coupling:

- End Closure: Forged caps provide secure sealing at the end of pipes, effectively stopping the flow of fluids or gases.

- Pressure Containment: Designed to handle high-pressure conditions, these caps contribute to the safety of piping systems by containing internal pressure.

- Durability: Crafted through forging, they gain exceptional strength and durability, ensuring long-lasting performance.

- Material Variety: Available in diverse materials like carbon steel, stainless steel, and alloys, chosen based on factors such as corrosion resistance and application needs.

- Easy Installation: Capable of being welded or threaded onto pipe ends, they offer straightforward installation and integration.

- Protection: By covering pipe openings, forged caps shield against contaminants and external elements that could compromise system integrity.

Application across Industries:

- Oil and Gas: Used in pipelines and refineries for their ability to withstand high pressures and harsh conditions, ensuring secure connections in the transport of oil and gas.

- Chemical Processing: Employed to connect pipes carrying corrosive chemicals, benefiting from their corrosion resistance and durability.

- Power Generation: Utilized in power plants for connecting pipes carrying steam or other fluids under high temperatures and pressures.

- Water Treatment: Applied in water treatment facilities to connect pipes carrying treated water or chemicals, maintaining leak-free connections.

- Marine: Found in shipbuilding and marine industries, connecting pipes carrying fluids in vessels subjected to saltwater and varying pressures.

Crafted from an extensive array of materials and grades, our Forged Caps are tailored to cater to the distinct needs of clients across a diverse spectrum of industries.

STAINLESS STEEL & DUPLEX STEEL CAPS:

Specifications:

- Size : 1/2″ NB to 4″ NB, (Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Stainless Steel : ASTM A 182 F – 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A 182 F -51,F 53, F 55

ALLOY STEEL, CARBON STEEL & LTCS CAPS:

Specifications:

- Size : 1/2″ NB to 4″ NB, (Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Alloy Steel : ASTM A 182-F5,F9,F11,F21,F22 & F91

- Carbon Steel : ASTM A 105

- Low Temperature Carbon Steel : A 350 LF2

- Other Services : Hot Dip Galvanizing, Sand Blasting, Customized Machining

COPPER & NICKEL ALLOYS CAPS:

Specifications:

- Size : 1/2″ NB to 4″ NB(Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400, N05500

- Inconel : UNS N06600, N06601, N06625, N08800, N08810, N08825,

- Hastelloy : UNS N10276, N06022, N10665, N06455,

- Titanium : Gr. 1,2.3, DTH 3.7025, DTH 3.7035, DTH 3.7055

- SMO 254 : UNS S31254

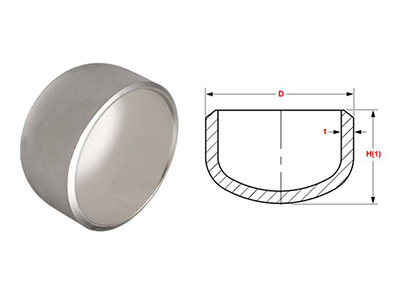

CAP

Alloyed Sustainables LLP is a distinguished Manufacturer of Forged Caps. Our products are meticulously crafted from premium materials in adherence to international standards, our forged caps epitomize unparalleled quality and reliability. Our steadfast commitment to excellence guarantees that you receive only the finest products, providing secure and dependable solutions that cater to a wide array of industries.

Description:

Forged caps, also referred to as forged pipe caps or forged end caps, serve as vital elements within piping systems, tasked with effectively sealing the termination of a pipe. Designed meticulously, these fittings encapsulate the exposed end of a pipe or tube, imparting a resilient shield that halts the passage of fluids or gases. Their widespread application spans diverse sectors, encompassing industries like oil and gas, petrochemicals, chemicals, power generation, and beyond.

Key Features of Forged Coupling:

- End Closure: Forged caps provide secure sealing at the end of pipes, effectively stopping the flow of fluids or gases.

- Pressure Containment: Designed to handle high-pressure conditions, these caps contribute to the safety of piping systems by containing internal pressure.

- Durability: Crafted through forging, they gain exceptional strength and durability, ensuring long-lasting performance.

- Material Variety: Available in diverse materials like carbon steel, stainless steel, and alloys, chosen based on factors such as corrosion resistance and application needs.

- Easy Installation: Capable of being welded or threaded onto pipe ends, they offer straightforward installation and integration.

- Protection: By covering pipe openings, forged caps shield against contaminants and external elements that could compromise system integrity.

Application across Industries:

- Oil and Gas: Used in pipelines and refineries for their ability to withstand high pressures and harsh conditions, ensuring secure connections in the transport of oil and gas.

- Chemical Processing: Employed to connect pipes carrying corrosive chemicals, benefiting from their corrosion resistance and durability.

- Power Generation: Utilized in power plants for connecting pipes carrying steam or other fluids under high temperatures and pressures.

- Water Treatment: Applied in water treatment facilities to connect pipes carrying treated water or chemicals, maintaining leak-free connections.

- Marine: Found in shipbuilding and marine industries, connecting pipes carrying fluids in vessels subjected to saltwater and varying pressures.

Crafted from an extensive array of materials and grades, our Forged Caps are tailored to cater to the distinct needs of clients across a diverse spectrum of industries.

STAINLESS STEEL & DUPLEX STEEL CAPS:

Specifications:

- Size : 1/2″ NB to 4″ NB, (Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Stainless Steel : ASTM A 182 F – 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A 182 F -51,F 53, F 55

ALLOY STEEL, CARBON STEEL & LTCS CAPS:

Specifications:

- Size : 1/2″ NB to 4″ NB, (Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Alloy Steel : ASTM A 182-F5,F9,F11,F21,F22 & F91

- Carbon Steel : ASTM A 105

- Low Temperature Carbon Steel : A 350 LF2

- Other Services : Hot Dip Galvanizing, Sand Blasting, Customized Machining

COPPER & NICKEL ALLOYS CAPS:

Specifications:

- Size : 1/2″ NB to 4″ NB(Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400, N05500

- Inconel : UNS N06600, N06601, N06625, N08800, N08810, N08825,

- Hastelloy : UNS N10276, N06022, N10665, N06455,

- Titanium : Gr. 1,2.3, DTH 3.7025, DTH 3.7035, DTH 3.7055

- SMO 254 : UNS S31254