SWAGE NIPPLES FORGED FITTINGS

Alloyed Sustainables LLP is a leading manufacturer of premium swage nipples. These components are made of high-quality materials that meet both national and international requirements. Our dedication to quality guarantees that only superior products reach you, providing dependable and safe solutions for a wide range of sectors. Alloyed Sustainables is your top choice for high-quality swage nipples that contribute to your success, thanks to a devoted team and a variety of solutions.

Description:

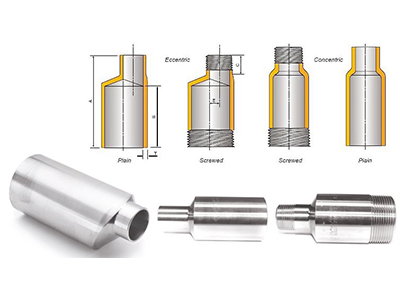

A Forged Swage Nipple is a pipe fitting that is used to connect two pipelines of different diameters. It enables a smooth transition between pipelines of different sizes, which aides in the preservation of the flow characteristics and structural integrity of the piping system.

Swage nipples can be concentric or eccentric and are widely utilized in industries including oil and gas, petrochemicals, and chemical processing, among others. They are designed to be threaded or welded onto pipelines to assure the strength and dependability of the piping system.

Key Features of Swage Nipples:

- Size Transition:Swage nipples facilitate smooth transitions between pipes of different sizes, vital for maintaining flow characteristics in piping systems.

- Concentric and Eccentric Types: Available in concentric (gradual transition) and eccentric (abrupt transition) variants, offering flexibility in accommodating various needs.

- Reducing and Enlarging: Mainly used to reduce pipe sizes, but can also enlarge pipes as needed in specific situations.

- Pressure Ratings: Designed to meet specific pressure requirements, varying based on material, size, and design.

- Easy Installation: Simple installation, threaded versions can be easily attached, though welding requires appropriate techniques.

Application across Industries:

- Oil and Gas: Used for connecting pipelines of varying sizes, aiding in fluid transport and distribution in upstream, midstream, and downstream operations.

- Chemical Processing: Facilitates fluid transfer between reactors, vessels, and processing units, crucial for maintaining efficient chemical production.

- Power Generation: Used in power plants for connecting pipes carrying steam, water, or other fluids, contributing to energy generation processes.

- Water Treatment: Aids in connecting pipes of different diameters in water treatment facilities, ensuring proper flow rates and treatment efficiency.

Our Forged Swage Nipples are fabricated using a diverse range of materials and grades to cater to the unique demands of clients across a broad spectrum of industries.

STAINLESS STEEL & DUPLEX STEEL SWAGE NIPPLES:

Specifications:

- Size : 1/2″ NB to 4″ NB, (Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Stainless Steel : ASTM A 182 F – 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A 182 F -51,F 53, F 55

ALLOY STEEL, CARBON STEEL & LTCS SWAGE NIPPLES:

Specifications:

- Size : 1/2″ NB to 4″ NB, (Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Alloy Steel : ASTM A 182-F5,F9,F11,F21,F22 & F91

- Carbon Steel : ASTM A 105

- Low Temperature Carbon Steel : A 350 LF2

- Other Services : Hot Dip Galvanizing, Sand Blasting, Customized Machining

COPPER & NICKEL ALLOYS SWAGE NIPPLES:

Specifications:

- Size : 1/2″ NB to 4″ NB(Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400, N05500

- Inconel : UNS N06600, N06601, N06625, N08800, N08810, N08825,

- Hastelloy : UNS N10276, N06022, N10665, N06455,

- Titanium : Gr. 1,2.3, DTH 3.7025, DTH 3.7035, DTH 3.7055

- SMO 254 : UNS S31254

SWAGE NIPPLES FORGED FITTINGS

Alloyed Sustainables LLP is a leading manufacturer of premium swage nipples. These components are made of high-quality materials that meet both national and international requirements. Our dedication to quality guarantees that only superior products reach you, providing dependable and safe solutions for a wide range of sectors. Alloyed Sustainables is your top choice for high-quality swage nipples that contribute to your success, thanks to a devoted team and a variety of solutions.

Description:

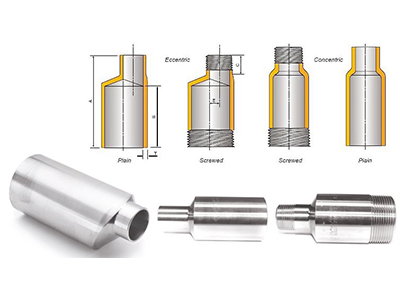

A Forged Swage Nipple is a pipe fitting that is used to connect two pipelines of different diameters. It enables a smooth transition between pipelines of different sizes, which aides in the preservation of the flow characteristics and structural integrity of the piping system.

Swage nipples can be concentric or eccentric and are widely utilized in industries including oil and gas, petrochemicals, and chemical processing, among others. They are designed to be threaded or welded onto pipelines to assure the strength and dependability of the piping system.

Key Features of Swage Nipples:

- Size Transition:Swage nipples facilitate smooth transitions between pipes of different sizes, vital for maintaining flow characteristics in piping systems.

- Concentric and Eccentric Types: Available in concentric (gradual transition) and eccentric (abrupt transition) variants, offering flexibility in accommodating various needs.

- Reducing and Enlarging: Mainly used to reduce pipe sizes, but can also enlarge pipes as needed in specific situations.

- Pressure Ratings: Designed to meet specific pressure requirements, varying based on material, size, and design.

- Easy Installation: Simple installation, threaded versions can be easily attached, though welding requires appropriate techniques.

Application across Industries:

- Oil and Gas: Used for connecting pipelines of varying sizes, aiding in fluid transport and distribution in upstream, midstream, and downstream operations.

- Chemical Processing: Facilitates fluid transfer between reactors, vessels, and processing units, crucial for maintaining efficient chemical production.

- Power Generation: Used in power plants for connecting pipes carrying steam, water, or other fluids, contributing to energy generation processes.

- Water Treatment: Aids in connecting pipes of different diameters in water treatment facilities, ensuring proper flow rates and treatment efficiency.

Our Forged Swage Nipples are fabricated using a diverse range of materials and grades to cater to the unique demands of clients across a broad spectrum of industries.

STAINLESS STEEL & DUPLEX STEEL SWAGE NIPPLES:

Specifications:

- Size : 1/2″ NB to 4″ NB, (Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Stainless Steel : ASTM A 182 F – 304 / 304H / 304L / 316 / 316H / 316L / 316Ti / 309 / 310 / 317L / 321 / 347 / 904L / Alloy 20

- Duplex Steel : ASTM A 182 F -51,F 53, F 55

ALLOY STEEL, CARBON STEEL & LTCS SWAGE NIPPLES:

Specifications:

- Size : 1/2″ NB to 4″ NB, (Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Alloy Steel : ASTM A 182-F5,F9,F11,F21,F22 & F91

- Carbon Steel : ASTM A 105

- Low Temperature Carbon Steel : A 350 LF2

- Other Services : Hot Dip Galvanizing, Sand Blasting, Customized Machining

COPPER & NICKEL ALLOYS SWAGE NIPPLES:

Specifications:

- Size : 1/2″ NB to 4″ NB(Socket Weld & Threaded)

- Class : 3000#, 6000#, 9000#, in ANSI/ASME B 16.11

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400, N05500

- Inconel : UNS N06600, N06601, N06625, N08800, N08810, N08825,

- Hastelloy : UNS N10276, N06022, N10665, N06455,

- Titanium : Gr. 1,2.3, DTH 3.7025, DTH 3.7035, DTH 3.7055

- SMO 254 : UNS S31254